3D Laser Scanning for Oil and Gas Applications

3D Laser Scanning for Oil and Gas Applications

GPRS is experienced in providing 3D laser scanning services in oil and gas applications to produce reliable, high quality data that can be used across your organization. We have experience scanning refineries, process areas and distribution facilities all over the United States. We can high definition laser scan the interior and exterior of buildings; structural, mechanical, electrical and plumbing features; equipment and piping down to ½ inch diameter; and any other site topography and features.

Our Experience

Our laser scanning experience in oil and gas applications include:

- Refineries

- Terminals

- Super Structures

- LPG Facilities

- Natural Gas Compression Stations

- Vapor Recovery Units (VRUs)

- Small and Large Format Piping

- Valves

- Tanks

- Loading Racks

- Ethanol Pump Stations and Offload Areas

- Natural Gas Separator Units

- Metering Skids

- Freighter Piers

- Tower, Platforms and Bridges

- Pipeline Manifold Shelters

- Dock Connection Piping

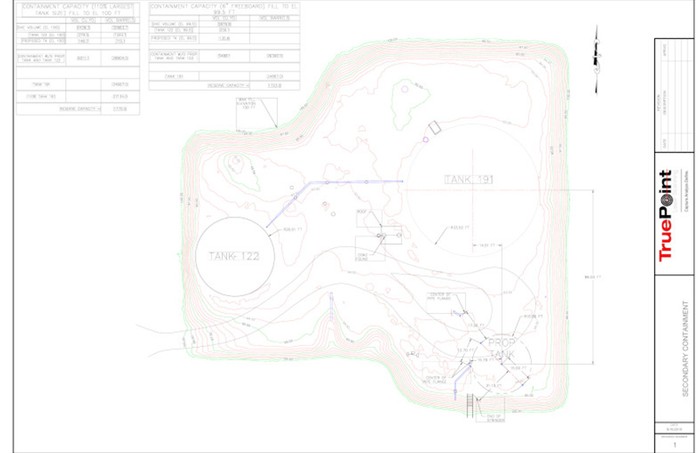

- Secondary Containment Areas

Benefits of Laser Scanning

Laser Scanning is SAF – Safe, Accurate and Fast. 3D laser scanning allows GPRS to provide clients with precise data in a short amount of time. Our scan specialists accurately and efficiently capture data in locations where accessibility is difficult and areas are unsafe. The smallest details can be captured in highly congested areas. The inside of tanks and containment dykes can be laser scanned for volume calculations and deformation analysis. Laser scanning provides more information than tank strapping. GPRS can provide reliable, accurate as-built information for facility upgrades and expansions. 3D laser scanning can aid in design, construction sequencing and scheduling, clash detection or pre-fabrication, plus reduce site revisits due to missed measurements, schedule delays and change orders. All of GPRS’s scan technicians have a minimum of OSHA-10 training to ensure they understand safe practices while on-site and how to minimize potential dangers associated with these types of facilities.

Deliverables and Services

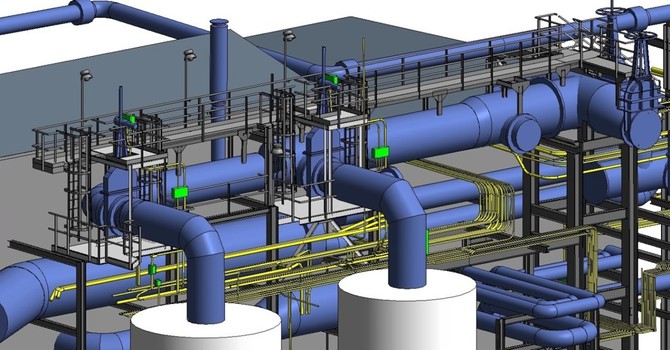

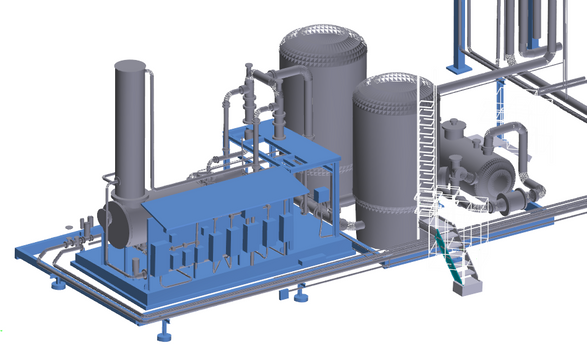

BIM/CAD deliverables can be provided in a variety of formats including AutoCAD Plant 3D, Navisworks, Bentley MicroStation, Revit, AutoCAD MEP, or simple AutoCAD solids.

Point cloud deliverables can include file formats such as:

- Leica (.pts, .ptx, .ptg)

- Autodesk Recap (.rcs and/or .rcp)

- Bentley (.pod)

Additional services include 2D site plans and 3D BIM models in additional Autodesk products such as AutoCAD Civil 3D. Leica TruViews and full color photographs complement the deliverables and further expand on details from laser scan data in a standard Microsoft Windows environment.

Data can be used to create accurate as-builts of the facility, aid in the generation of isometric drawings and for clash detection and pre-fabrication purposes.

Our engineers can work closely with clients to develop project phasing and sequencing, custom equipment tagging, pipe scheduling and sorting phasing in Revit. They can assign properties of pipes including pipe material specifications and conduct volume calculations and deformation analysis. We can use ClearEdge 3D Edgewise software to process piping and build custom libraries specific to client needs. Custom Revit families can also be generated to build a library of custom content.

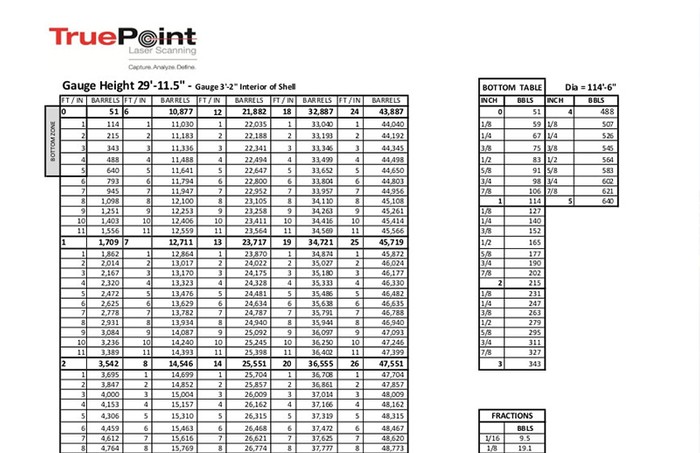

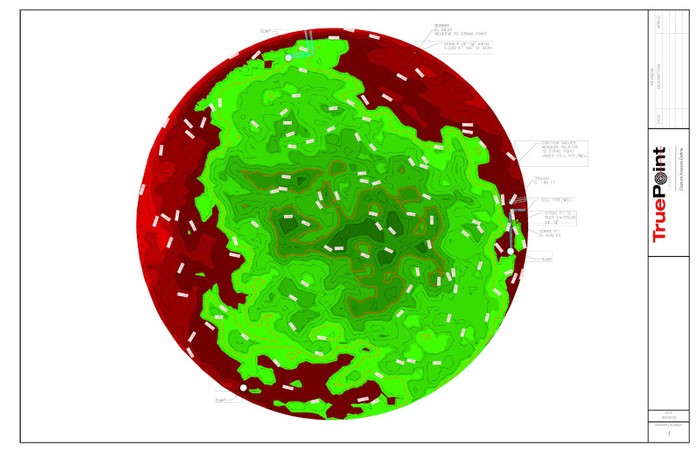

Storage Tank Strapping Services

GPRS 3D Laser Scanning provides tank calibration services, commonly known as "tank strapping," which is the procedure for measuring storage tanks to provide accurate dimensions for capacity table calculations.

GPRS safely measures all the possible details of storage tanks, including vertical wall roundness and shape, sumps, piping, columns, floating roofs, interior features and floor profiles. Once all the necessary measurements are recorded, customized tank strapping charts are created for clients to determine what volume is in their tank at a specific level. GPRS tank strapping professionals use established calibration methods, tables and equipment conforming to current API industry standards to any standard unit of measure.

GPRS’s tank strapping expertise is available for:

- Fixed roof tanks

- Floating roof tanks

- Onshore bulk storage tanks

- Vessels storage compartment (storage tanks on crude oil tankers, LNG vessels, etc.)

- Storage tanks on trucks and railcars

- Calibration of tank bottoms

- Agricultural and chemical silos and elevators

GPRS’s team of in-house engineers works with each client to create custom deliverables, including point cloud data, AutoCAD drawings, 3D models, floor contour drawings, JetStream .LGS files, PDFs, and Excel files of strapping tables.

For storage tank strapping services, contact GPRS today at Laser@gprsinc.com or 419-843-7226 (SCAN).

3D Laser Scanning Pricing

The cost of 3D laser scanning can vary widely depending on your project scope. GPRS customizes every quote specific to your project’s needs. GPRS Project Managers use 3D laser scanners to capture every detail of your site, delivering building dimensions, locations, and layout with millimeter accuracy. This can include the aboveground structural, architectural, and MEP features, plus underground utility and concrete markings. Our Mapping & Modeling Team can deliver point clouds, 2D CAD drawings, 3D BIM models, 3D Mesh models, TruViews, and Virtual Tours at any level of detail.

How Can GPRS Help You?

Laser scanning is a great facility documentation and management tool with benefits that can be realized many times throughout the life of a facility. Our scan technicians, engineers and CAD designers work together to help you control costs and complete projects on time and within budget. We have an excellent safety record, and have never had a loss work day due to injury.

Contact GPRS today at 419-843-SCAN (7226) or email us at Laser@gprsinc.com for more information about laser scanning services for oil and gas applications. We’re currently offering 10-minute presentations – would you like to schedule one? Click here.

Sample Projects for Oil and Gas Applications

Storage tank contour floor plan.

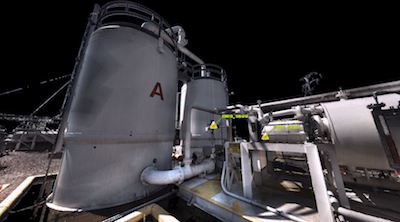

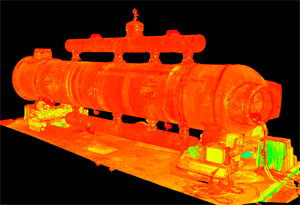

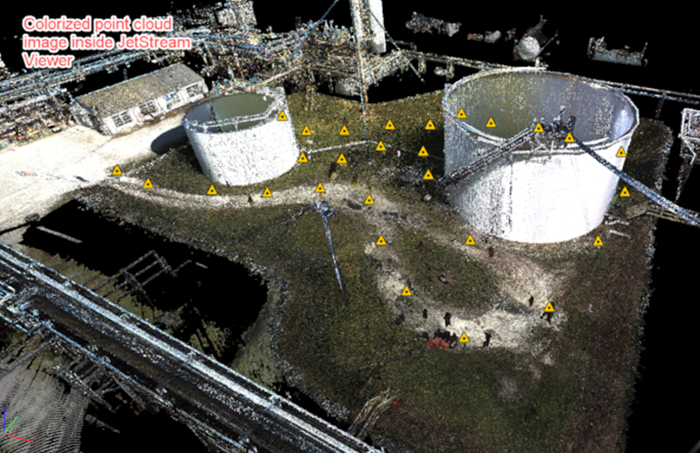

Screenshot of the point cloud information as seen in JetStream Viewer software.

Plan view containment with scanner locations.

Colorized point cloud image inside Jetstream Viewer.

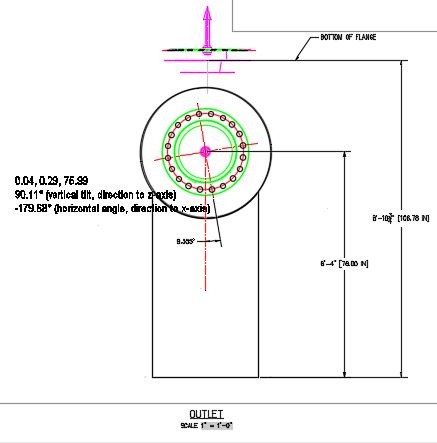

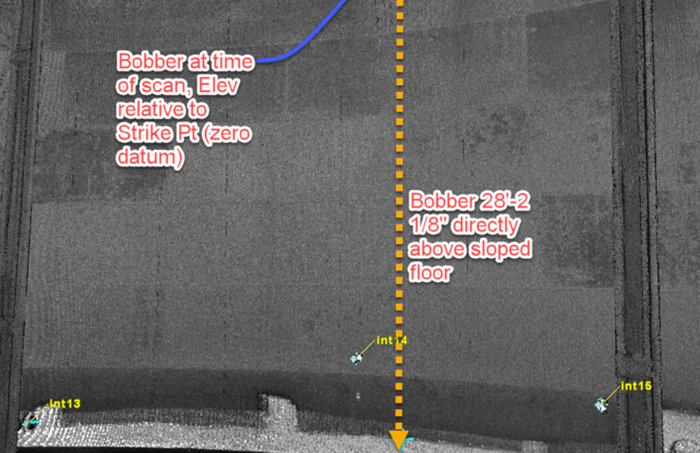

Bobber elevation screen capture.

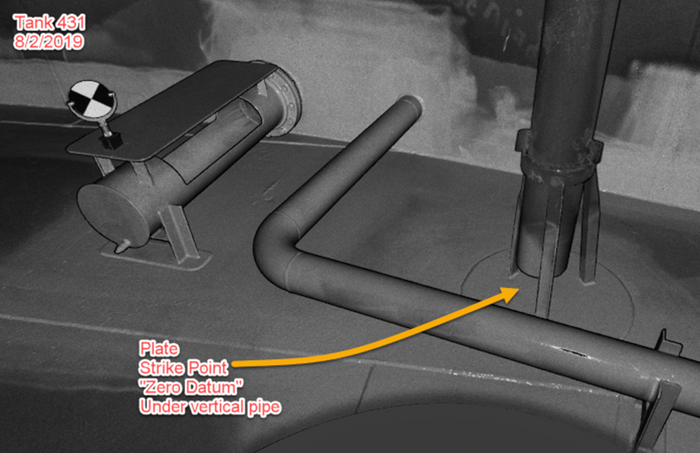

Storage tank datum snapshot.