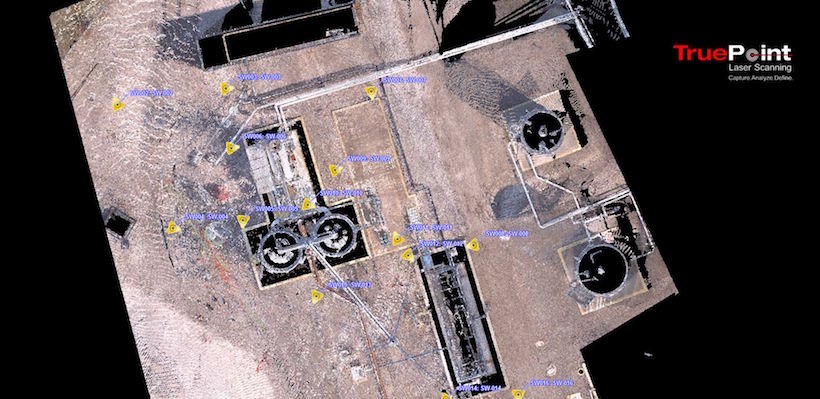

TruView of the Vapor Recovery Unit at a Fuel Distribution Company.

Case Study: Laser Scanning a Vapor Recovery Unit for Facility Upgrades

Location: Near Grand Rapids, Michigan

Task: A fuel distribution company was implementing upgrades at one of their facilities. TruePoint’s task was to use Lidar technology to laser scan a Vapor Recovery Unit (VRU), capturing piping, tanks and other mechanical, electrical and plumbing features. The client requested a 3D model of the VRU.

Challenge: The client was under a tight timeline to plan their project and implement upgrades at the facility. Traditional measurement methods and conversion to a 3D model would be time consuming and more costly.

Solutions: Utilizing the Leica P-40 Scan Station, TruePoint was able to capture laser scan data quickly, as well as capture panoramic photographs. The panoramic photographs overlaid the point cloud data colorizing the data points with real world color. Utilizing the point cloud to plan their facility upgrades, the client will avoid project delays, change orders and facility down time.

Deliverables: TruePoint’s experienced team of CAD technicians provided a colorized point cloud for use in MicroStation and TruViews.

Added Value: TruePoint’s great relationship with the client allowed them to coordinate mobilizations and discuss the project as it commenced. This allowed TruePoint to spend more time laser scanning the key features that were most important to them.

For 3D laser scanning of oil and gas facilities or terminal distribution centers in the state of Michigan please contact TruePoint at 734-807-0117.

Utilizing the Leica P-40 Scan Station, TruePoint was able to capture laser scan data quickly.

Utilizing the point cloud to plan their facility upgrades, the client will be able to avoid project delays, change orders and facility down time.