Clash Detection

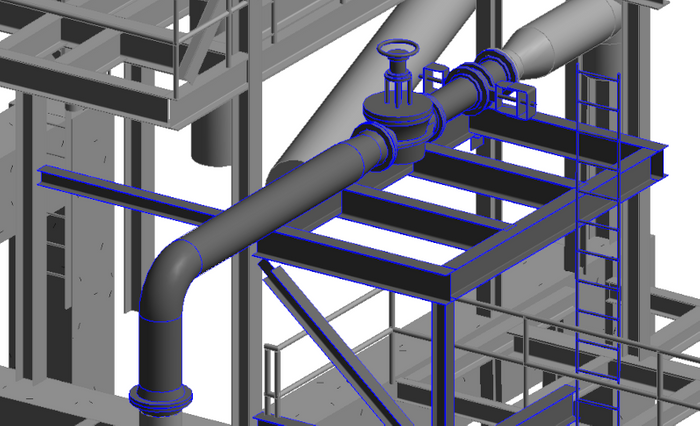

3D Laser Scanning for Clash Detection and Prefabrication

3D laser scanning captures as-built site conditions with 2-6 millimeter accuracy, helping to identify potential clashes, prefabricate components, and plan a flawless installation. Data collected can be shared across project teams to have one single source of information. Accurate design planning and team communication minimizes clashes, installation problems, and rework. This saves time, money, and headaches by preventing costly modifications in the field.

3D Laser Scanning for Clash Detection

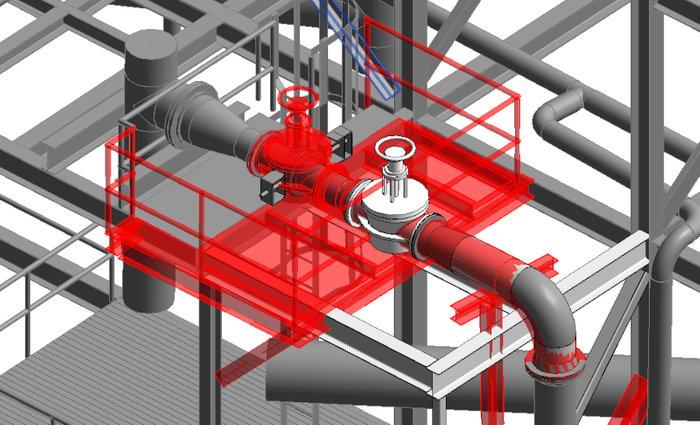

Construction and engineering teams use the process of clash detection to identify and resolve clashes or conflicts between different elements of a design. These clashes can occur when components of an existing building, structure, or system and new design elements intersect or conflict in space.

Clash detection is commonly performed with a Building Information Model (BIM), utilized to ensure that all building elements fit together seamlessly. By using a BIM model, designers and engineers can identify and resolve clashes between structural, architectural, mechanical, electrical, and plumbing (MEP) systems in the design process before construction begins.

Clash detection is a valuable tool in construction and engineering to ensure that building elements are coordinated and conflicts are resolved before they impact the construction process. Performing clash detection ensures the smooth installation of components and greatly reduces rework and project delays.

How is 3D Laser Scanning Used for Clash Detection?

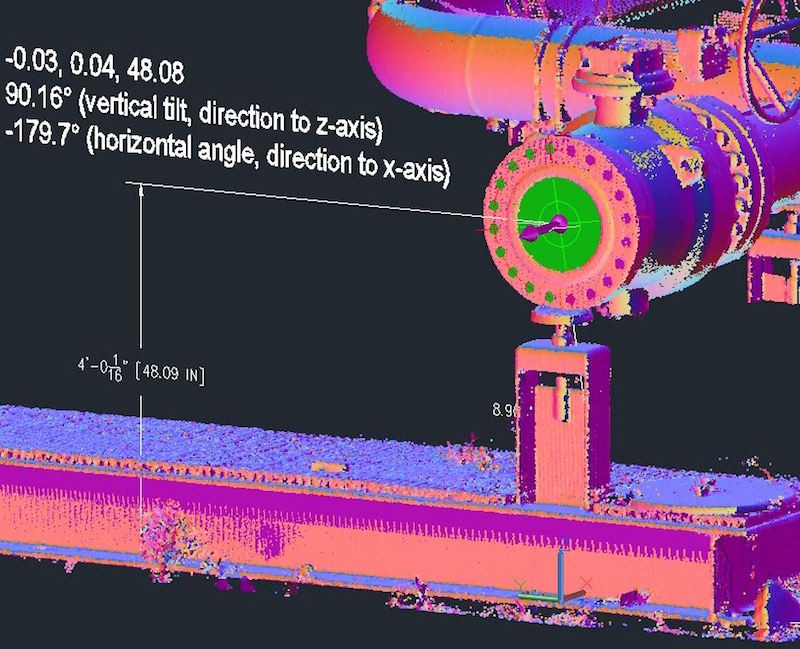

BIM models are created with a point cloud that is captured by a 3D laser scanner. GPRS utilizes Leica laser scanners to capture as-built site conditions with 2-6 millimeter accuracy.

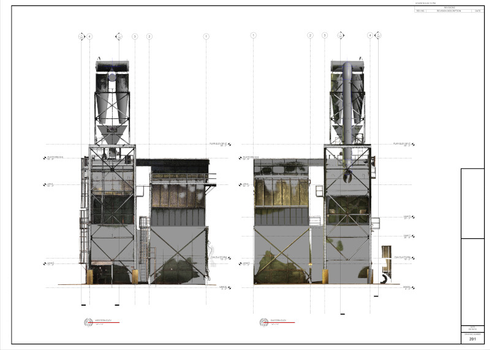

GPRS 3D laser scanning services delivers clients an accurate set of real-time data which can be compared against the design model or processed into a customized and integrated 3D BIM model at any level of detail.

3D laser scanning can be completed during many phases of construction, as trades complete their work to capture progressive as-built conditions, delivering accurate structural details and MEP fit-out. Data can be collected to update the model on a continual basis. This method of progressive data capture delivers a more accurate as-built model for clients.

How are 3D BIM Models Used for Clash Detection?

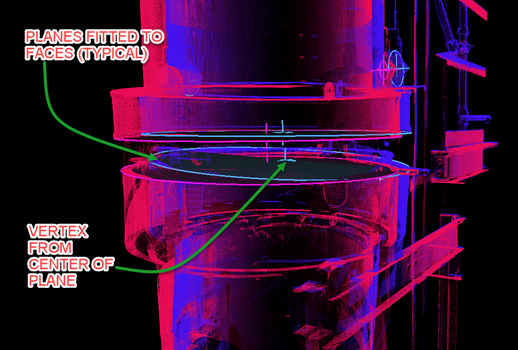

The GPRS Mapping & Modeling team can create a single 3D BIM model or model by discipline from the point cloud data, detailing existing architectural, structural, and MEP conditions.

This 3D BIM model will help clients evaluate if the new elements fit accurately within the existing structure and enable clash detection to identify conflicts between the design and as-built conditions. With a 3D BIM model, clients can virtually see what conflicts or overlaps in the project design plans. They can inspect each new component, pipe, or system within the as-built conditions and discover clashes.

As-built data and models can be shared across project teams to have one single source of information with SiteMap®, our industry-leading project and facility management software, to aid in construction and renovation planning.

What are the Benefits of Clash Detection?

- Identify and Resolve Clashes: Clash detection helps identify and resolve conflicts between various building elements such as structural components, mechanical, electrical, plumbing (MEP) systems, architectural features, and more. These clashes can include elements intersecting, conflicting in space, or violating design constraints.

- Improve Coordination: Clash detection improves coordination among different disciplines working on the project. It helps ensure that each aspect of the design fits together seamlessly, reducing rework and potential issues during construction.

- Enhance Design Quality: By detecting clashes early in the design process, designers can improve the overall quality of the design. Resolving clashes before construction begins can lead to a more efficient and cost-effective project.

- Minimize Errors and Rework: Clash detection helps minimize errors and rework during construction by addressing conflicts before they become an issue on-site.

- Cost and Time Savings: Clash detection helps prevent costly and time-consuming issues during construction. By addressing clashes before construction begins, the project team can save time and money for the project.

- Improve Safety and Functionality: By ensuring that all building elements fit together seamlessly, clash detection helps improve the overall safety and functionality of the building.

A 3D BIM model will help evaluate if the new elements fit within the existing structure and enable clash detection to identify conflicts between the design and as-built conditions.

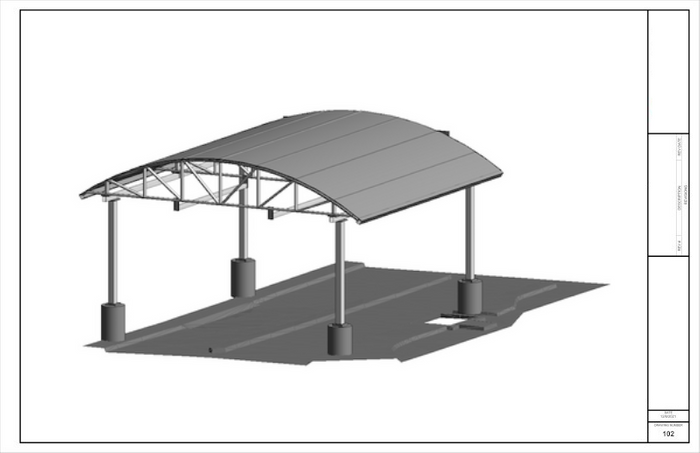

3D Laser Scanning for Prefabrication

Prefabrication is the practice of assembling components of a structure in a factory or other manufacturing site, and transporting complete assemblies to the construction site where the structure is to be located. For prefabrication to be successful, accurate component dimensional and location information is crucial. 3D laser scanning allows clients access to exact measurements to make fundamental calculations of building components for offsite manufacturing.

Any deviation in a prefabricated component may cause an assembly failure, leading to rework or reconstruction that can increase project duration and cost. By incorporating 2-6 millimeter-accurate laser scan data into prefabrication workflows will ensure that offsite construction elements fit perfectly in the installation space.

3D laser scanning can also be a critical part of the estimating process. 3D scanning can provide valuable details to estimators to understand the site’s context, evaluate labor and material costs, and prepare project timelines.

GPRS 3D Laser Scanning services provide 2-6 millimeter accuracy by capturing 2 million data points per second, for efficient planning, design, and construction.

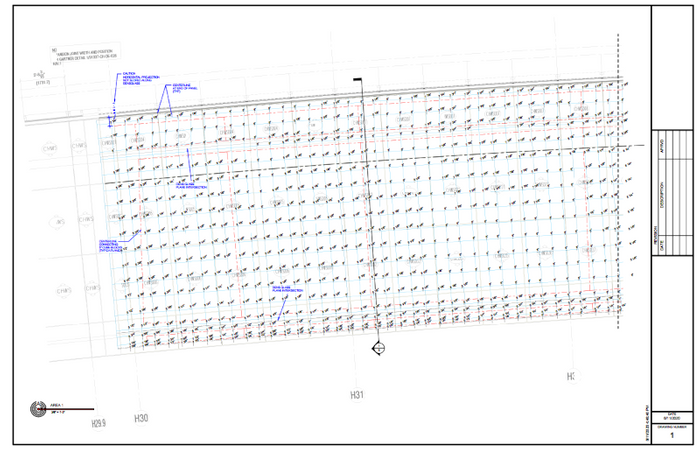

3D Laser Scanning Pricing

The cost of 3D laser scanning can vary widely depending on your project scope. GPRS customizes every quote specific to your project’s needs. GPRS Project Managers use 3D laser scanners to capture every detail of your site, delivering building dimensions, locations, and layout with 2-6 millimeter accuracy. This can include the aboveground structural, architectural, and MEP features, plus underground utility and concrete markings. Our Mapping & Modeling Team can deliver point clouds, 2D CAD drawings, 3D BIM models, 3D Mesh models, TruViews, and Virtual Tours at any level of detail.

Accurate data helps GPRS clients avoid expensive mistakes, reworks, and change orders. GPRS 3D Laser Scanning services provide 2-6 millimeter accuracy by capturing 2 million data points per second, for efficient planning, design, and construction.

With over 500 Project Managers in every major market and city across the United States, GPRS has an unmatched nationwide service network that makes it quick and easy to find an expert Project Manager in your area.

Human error is possible. GPRS 3D Laser Scanning and BIM Modeling services prove their value throughout construction projects as they minimize clash detection and prefabrication errors before project build-outs.

Contact us today at 419-843-7226 or Laser@gprsinc.com.

Related Case Studies

Quick Links

Client Testimonials

- "Our disciplines have been utilizing the point cloud and TruView information and it has been of value. We have discovered a few clashes with our structural steel, which may not have ever been caught, so I feel the service has already paid for itself." - Joseph G, P.E., Project Manager

- “We have been very pleased with the results of the scanning process. The product has been very useful. And has certainly helped in the development of the project. I would certainly use GPRS again on future projects.” - John G., President and Principal Architect

- “Thanks for jumping into this assignment so quickly. What a great and productive trip. You guys work tirelessly, non-stop with all aspects of the set-up and execution. Your ability to master the technology is a game changer for us.” - Don A., Executive Vice President, Director of Architecture, Engineering and Technology

- “The scan helped tremendously and has saved us quite a bit of time and trouble.” - Gene A., Mechanical Integrity Engineer

- “[The Technician] did a good job of getting up to speed and working with little or no direction, which helped us concentrate on our other needs on site.” - Steve H., Project Manager