3D Laser Scanning for Power, Process and Plant Applications

Facilities and Plant Laser Scanning

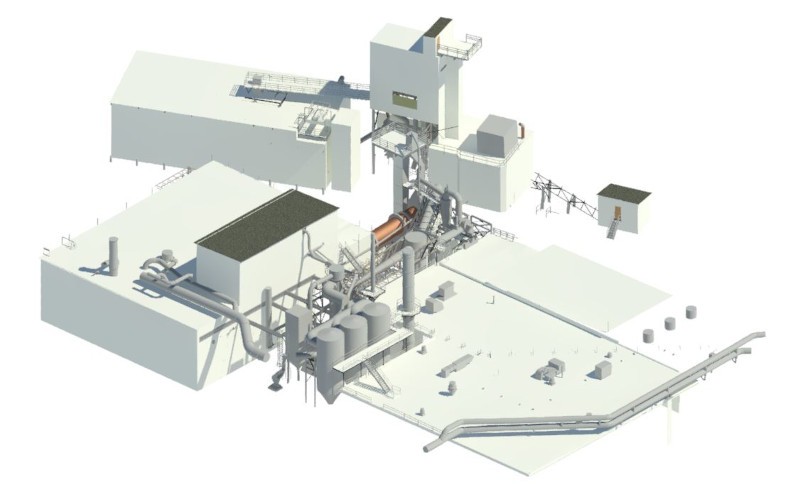

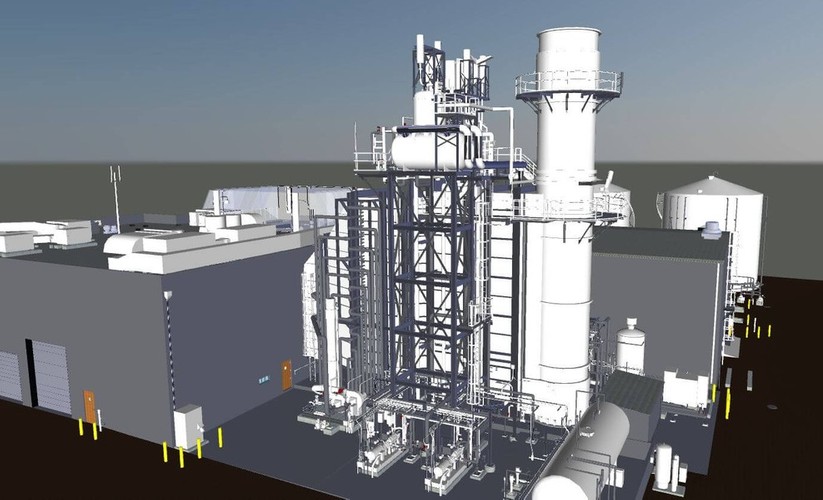

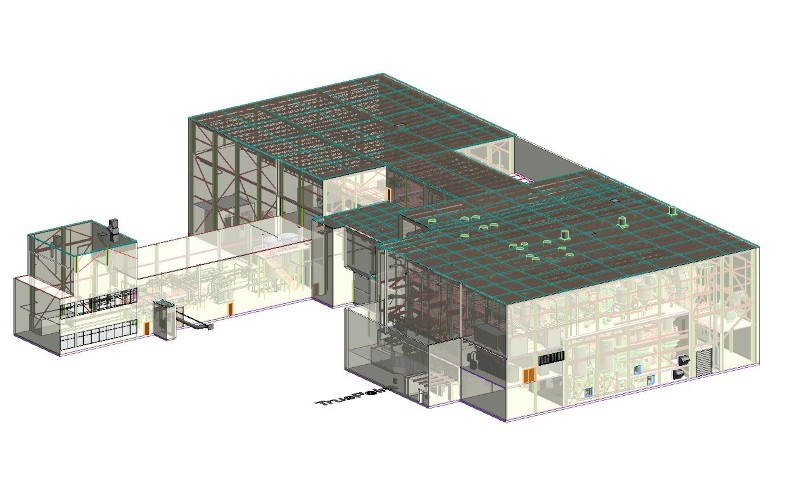

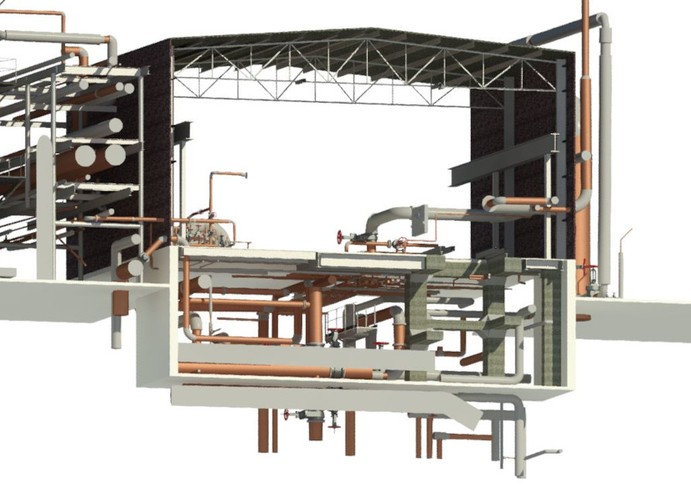

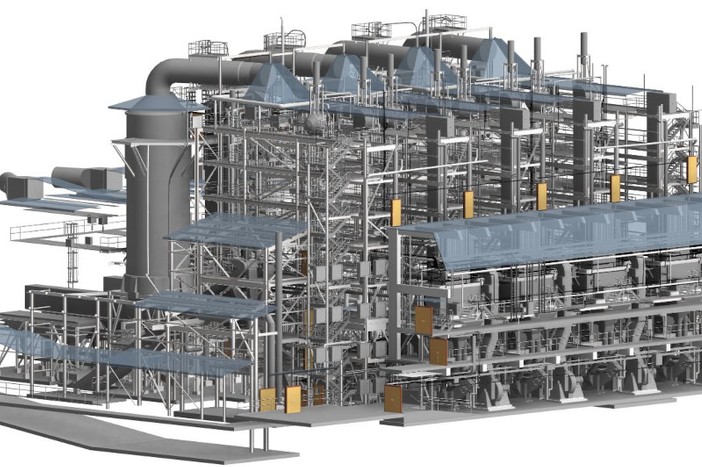

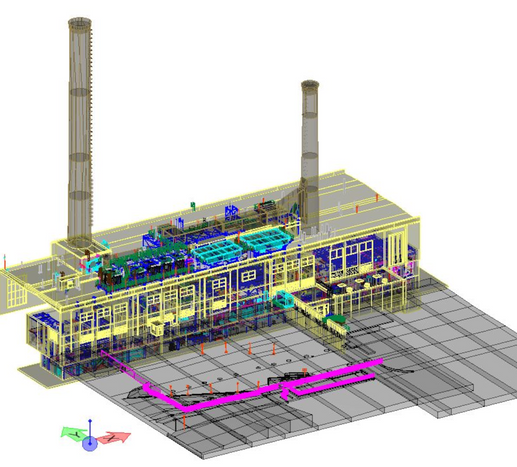

GPRS is experienced in providing 3D laser scanning services for Power, Process and Plant applications to produce reliable, high-quality data that can be used across your organization. We high-definition laser scan building infrastructure: structural, mechanical, electrical and plumbing features; furnaces, equipment, conduit and piping down to ½ inch diameter. We can work directly for municipalities, Engineering firms and privately owned facilities.

Our Experience

Our experience in Power, Process and Plant applications include:

- Industrial Facilities

- Food and Beverage Production

- Pharmaceutical Production

- Chemical Plants

- Specialty Ingredient

- Asphalt Plants

- Quarries, Stone and Other

- Substations

- High Voltage Transmission Lines

- Vegetation Inspection on Power Lines for Energy Companies

- Overhead Clearance

- Conveyors or Overhead Equipment

- Crane Placement

- Mechanical Rooms

- Steel Mills

- Paper Mills

- Manufacturing Plants

- Coking Plants

- Power Plants

- Steam Plants

- Telecommunications

- Hospitals and Universities

- Agricultural Cooperatives, Grain Facilities & Ethanol Plants

The Benefits of 3D Laser Scanning

3D laser scanning allows GPRS to provide clients with precise data in a short amount of time. Our scan technicians accurately and efficiently capture data in locations where accessibility is difficult and areas are unsafe. Laser scanning can be completed a distance away from energized equipment. The smallest details can be captured in highly congested areas. GPRS can provide reliable, accurate 3d industrial mapping for facility upgrades and expansions. 3D laser scanning can aid in design, construction sequencing and scheduling, plus reduce change orders.

Deliverables and Software

GPRS Deliverables

- Point Cloud Data (Raw Data)

- 2D CAD Drawings

- 3D Non-Intelligent Models

- 3D BIM Models

- 3D Mesh

- TruView | JetStream Viewer

- To learn more about deliverables, click here.

Customizable Deliverables

- Aerial Photogrammetry

- Comparative Analysis

- Deformation Analysis

- Digital Drawings of GPR Markings

- Floor Flatness Analysis/Contour Mapping

- New Construction Accuracy Analysis/Comparative Analysis

- Point Cloud Modeling Training Webinars

- Reconciliation of Clients 2D Design Drawings

- Reconciliation of Clients 3D Design Model

- Structural Steel Shape Probability Analysis

- Template Modeling

- Volume Calculations

- Wall Plumb Analysis

Modeling Options

- Standard Detail

- High Detail

- Very High Detail

Software We Are Trained In:

- Autodesk Recap

- Autodesk Revit

- Autodesk 3DS Max

- Autodesk Navisworks

- Autodesk AutoCAD Civil 3D

- Autodesk AutoCAD Map 3D

- Autodesk BIM 360

- Autodesk A360

- Autodesk Recap

- AutoCAD

- ArchiCAD

- Bentley MicroStation

- Bentley Descrates V8i

- ClearEdge 3D Edgewise

- Leica Cyclone

- FARO As-Built

- FARO Scene

- Scene 2go

- Scene Webshare

- Navis Indoor Viewer

- AVEVA LFM

- Cintoo

- CloudCompare

- Unreal Engine

- FileZilla

- ShareFile

- Dropbox

- Register 360

- JetStream Viewer

- TruView

- NavVis

- To learn more about software, click here.

3D Laser Scanning Pricing

The cost of 3D laser scanning can vary widely depending on your project scope. GPRS customizes every quote specific to your project’s needs. GPRS Project Managers use 3D laser scanners to capture every detail of your site, delivering building dimensions, locations, and layout with millimeter accuracy. This can include the aboveground structural, architectural, and MEP features, plus underground utility and concrete markings. Our Mapping & Modeling Team can deliver point clouds, 2D CAD drawings, 3D BIM models, 3D Mesh models, TruViews, and Virtual Tours at any level of detail.

Contact GPRS 3D Laser Scanning

Laser scanning is a great facility documentation and management tool with benefits that can be realized many times throughout the life of a facility. Our scan technicians, engineers and CAD designers work together to help you control costs and complete projects on time and within budget. We have an excellent safety record, and have never had a loss work day due to injury.

Contact GPRS Laser Scanning today at 419-843-SCAN (7226) or email us at Laser@gprsinc.com for more information about laser scanning services for Power, Process and Plant applications. We’re currently offering 10-minute presentations – would you like to schedule one? Click here.