3D Laser Scanning an Aluminum Recycling Plant

Project Manager Insight: “We completed three projects for this client over the course of a year. They see great value in having 3D data on hand to speed up the process of contractors beginning work on their respective areas.” -- Hunter Barnes, Project Manager

Location: Rosemount, MN

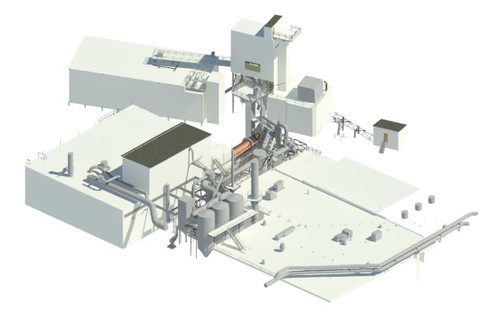

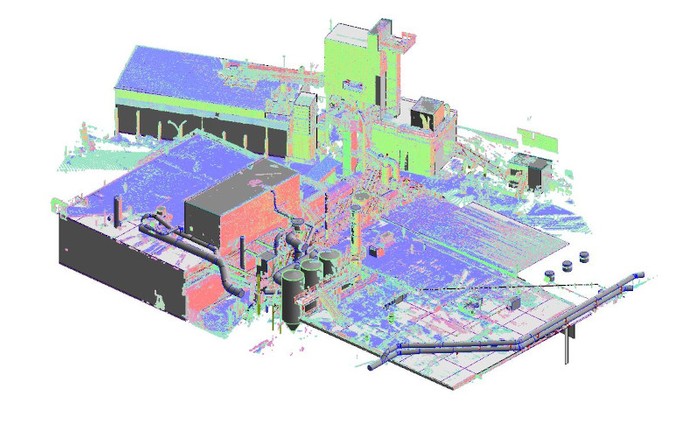

3D Laser Scanning Task: An aluminum recycling plant used TruePoint 3D laser scanning to document three areas of their plant for improvement projects. Recycling has seen rapid expansion over the last decade. There have been advances in technologies and systems for the collection, sorting and processing of materials. This client was redesigning areas to increase their efficiency in plant operations and workflow. All laser scanning was performed with a Leica P40 ScanStation survey-grade laser scanner containing a dual-axis compensator to achieve 2-4mm accuracy.

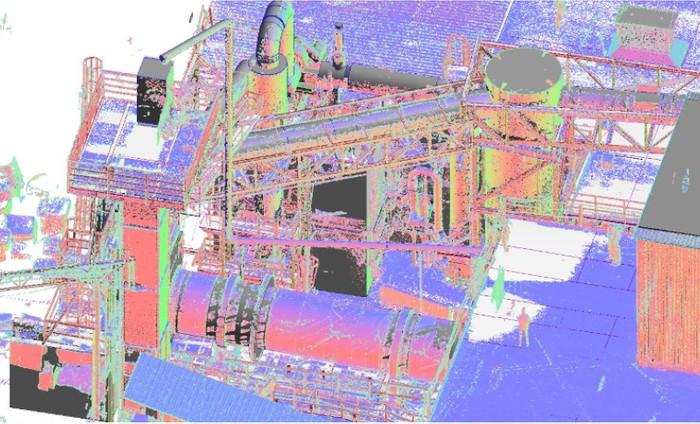

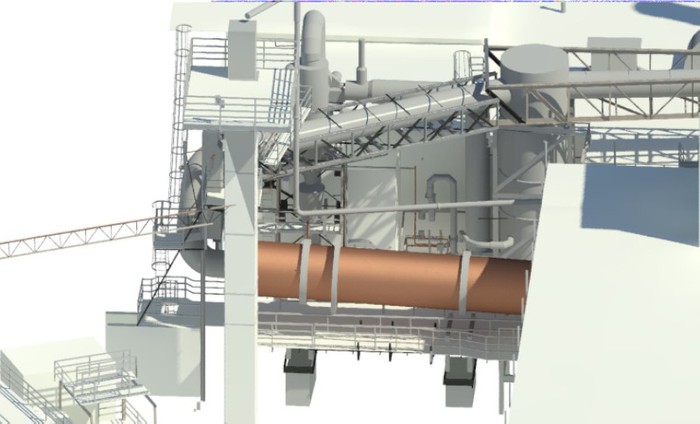

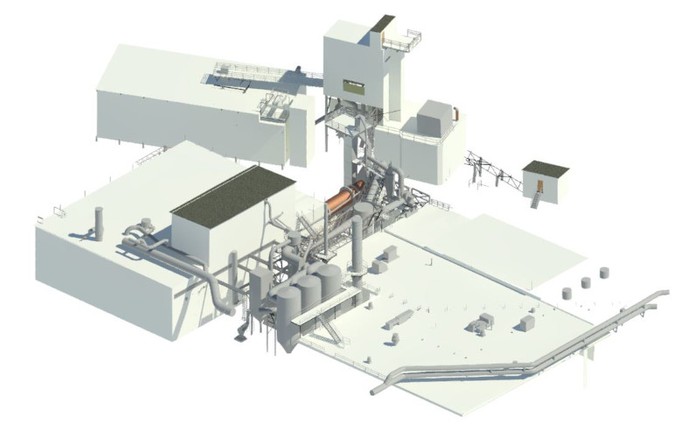

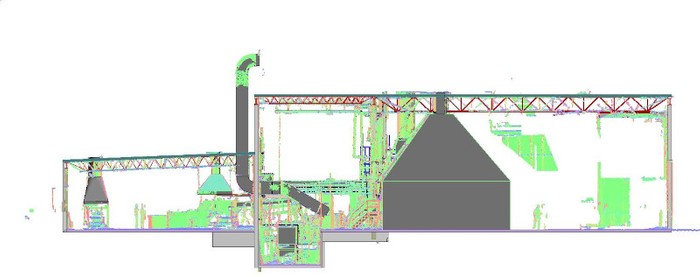

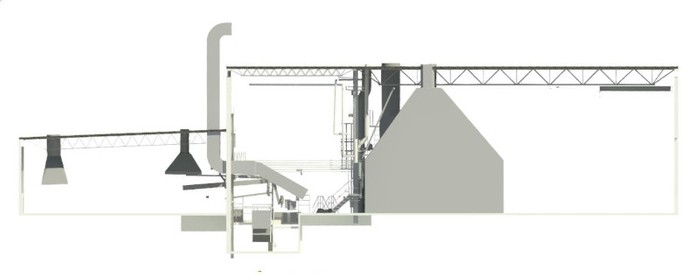

Dryer System Project: The facility dryer system was 3D laser scanned from the rooftop and ground level to capture structural elements, ductwork, furnace baghouse, kiln, and other essential equipment. The project manager met with the client to determine critical elements in each area and make sure they were captured. Examples include elbows in the duct work, the path of the ducts to the baghouses, details of the kiln and where it connects to the structure, and the surrounding machinery and conveyors in the recycling workflow.

Deliverables:

- Point Cloud file for Autodesk products (Recap .rcp containing .rcs files)

- Jetstream Viewer files

- 2D CAD Drawings

- LOD 200 3D Modeling

- • Basic structural elements including exposed columns and beams

- • Basic architectural elements of the exterior building envelope

- • MEP equipment and piping 2” in diameter and above

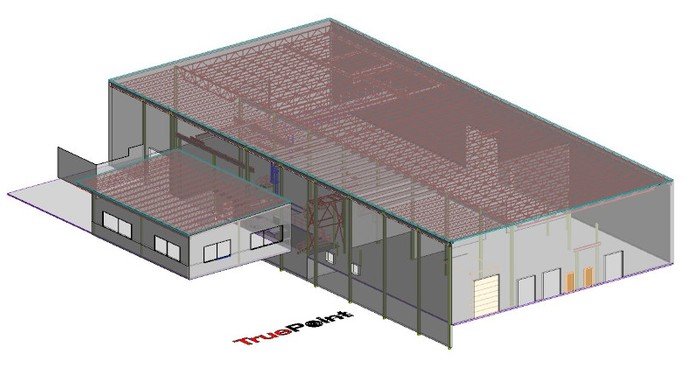

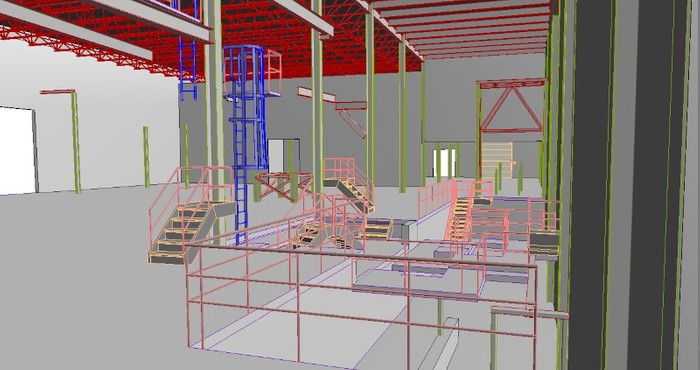

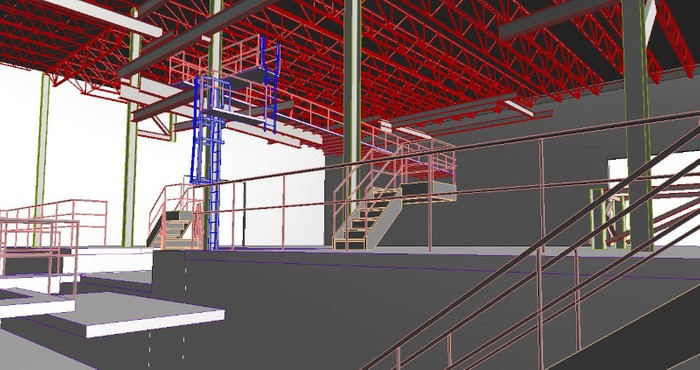

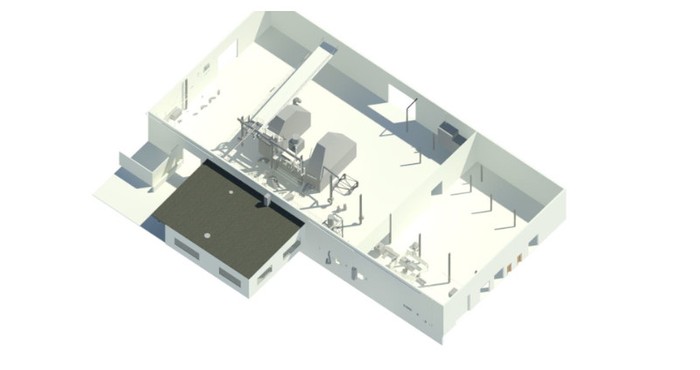

Building Documentation: One of the buildings in the facility was scanned to capture structural elements such as floors, walls, and ceilings; and various equipment, such as the casting line, tap and pit area.

Deliverables:

- Point Cloud file for Autodesk products (Recap .rcp containing .rcs files)

- Jetstream Viewer files

- LOD 300 3D Modeling

- Basic structural elements including exposed columns and beams

- Basic architectural elements of the exterior building envelope

- MEP Piping (2” and above), MEP Equipment, HVAC Ductwork

- Structural platforms, stairs, railings, framing, etc.

- Pit area, casting line, tap, and locations of existing equipment

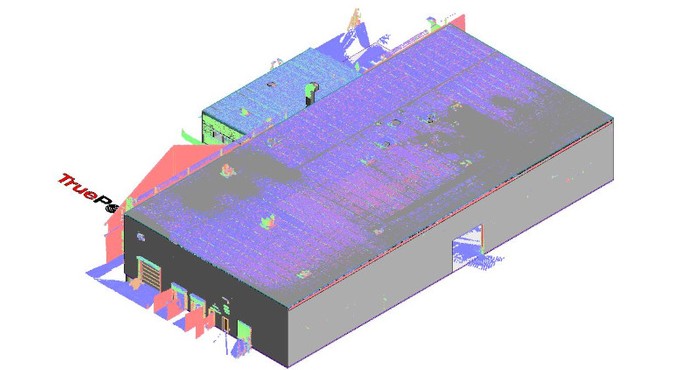

Main Furnace and Roof: The rooftop and area around the main furnace were 3D laser scanned to document the detailing of where the ducts penetrate the roofline. The client also needed roof dimensions for pick-up points where the new equipment will be mounted.

Deliverables:

- Point Cloud file for Autodesk products (Recap .rcp containing .rcs files)

About the Client: This client operates one of the highest efficiency aluminum recycling plants in the United States. Since 1973 they have been servicing large, medium and small foundries and die casters. The aluminum recycled is shipped to regional die casters and foundries where it is made into new products like lawn mower engines, ATV components, car parts and more.

3D Laser Scanning in Minnesota: For 3D laser scanning services in Minnesota, call 612-968-6524 or email minneapolis@truepointscanning.com. TruePoint is a nationally recognized leader in 3d laser scanning, providing laser scanning services for buildings, plants and facilities. We high-definition laser scan to create digital twins of building infrastructure: structural, mechanical, electrical and plumbing features; furnaces, equipment, conduit and piping down to ½ inch diameter. We can work directly for municipalities, engineering firms and privately owned facilities.

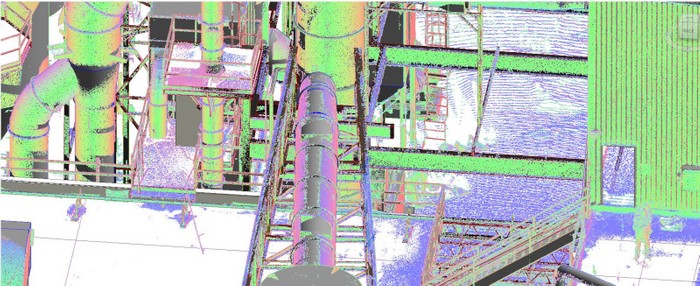

Point cloud of the dryer system, or raw data, shown in “normals” view.

Dryer system 3D model closeup created from the point cloud.

Point cloud screen capture showing the laser scan scope of the dryer system project.

3D model, sometimes referred to as a “digital twin,” of dryer system created from laser scan data.

Close up of scan data showing the pipe bridge, platforms, exhaust stacks and other plant components.

3D model of the pipe bridge, platforms, exhaust stacks and other plant components.

Exterior building photograph showing roof and detailing the pick-up points where the new equipment will be mounted.

3d model of aluminum recycling plant building exterior.

3d model of the recycling plant building interior.

3d model of recycling plant building interior.

Point cloud of building exterior shown in “normals” view.

3d model of recycling plant building interior.

View from the ground and pit level surrounding the furnace and conveyor systems.

3d model of the ground and pit level surrounding the furnace and conveyor systems.