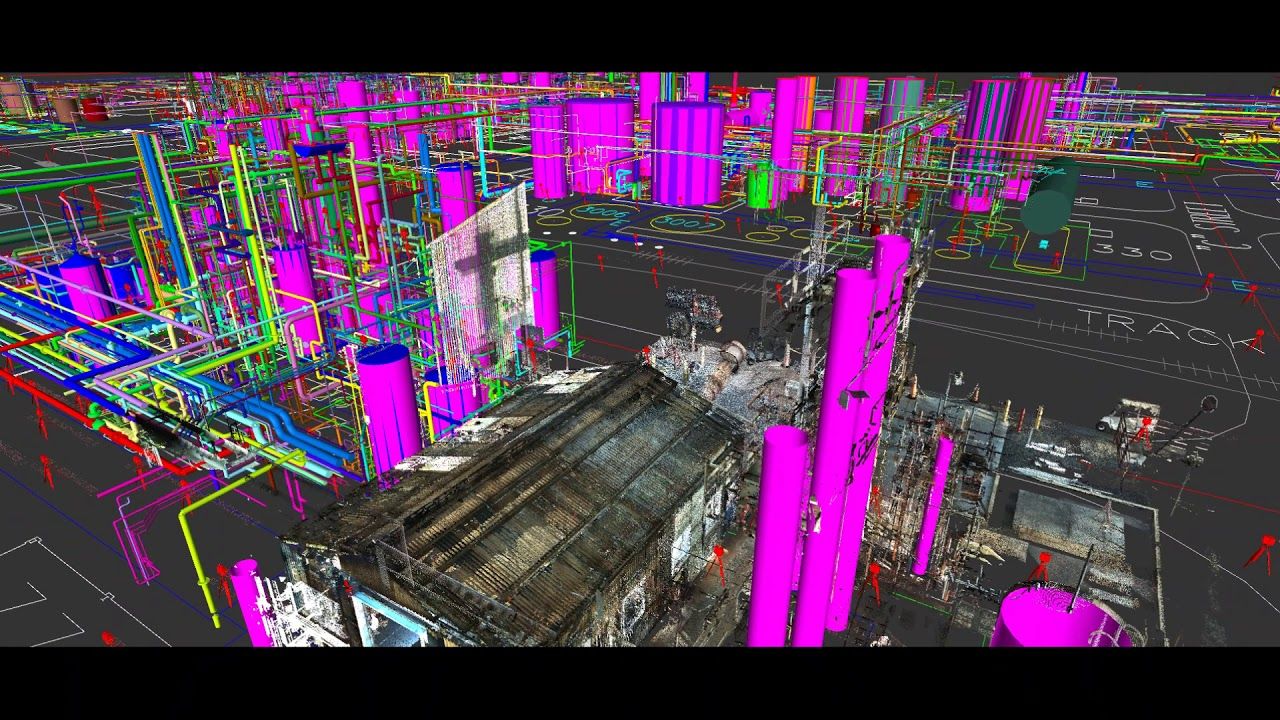

Case Study: 3D Laser Scanning A 40-Acre Chemical Processing Plant

Location: Western Kentucky

Task: TruePoint 3D laser scanned a 40-acre plant in Western Kentucky that provides specialty chemicals for a variety of industrial applications and personal care industries, such as pharmaceutical, food and beverage. TruePoint aided the client in the generation of isometric drawings for this 1955-built facility, which serves more than 100 countries. TruePoint laser scanned the interior and exterior of 20 buildings, tank farms, cooling towers, water treatment facilities, hazardous waste generators, refineries, retainage areas, processing towers, platforms and railroad tracks. The task was to high-definition survey all structural, mechanical, electrical and plumbing features, equipment and piping down to ½ inch diameter.

Challenge: The client estimated that it would have taken them over 10 years to complete this project using traditional survey methods. The size and complexity of the plant was their biggest challenge and they needed accurate documentation of the entire 40-acres to generate isometric drawings for maintenance and future plant modifications. The client did not wish to allocate internal human resources for this project nor did they have the in-house resources to complete this quickly. In addition, certain areas of the facility could only be accessed during a limited shut-down period and some areas were not accessible at all. Information needed to be captured accurately from high towers, and safely away from generators and hot steam pipes.

Solutions: TruePoint had multiple teams of laser scan technicians on-site full-time for 3 months and conducted a complete and accurate laser scan of the entire facility. TruePoint’s experienced laser scanners developed a strategy and plan to scan this 40-acre facility, utilizing multiple laser scanners for various environments and applications, such as the Leica C10, Leica P20, Leica HDS7000, Leica P40; plus register and process the data. TruePoint’s technicians determined the best method to laser scan safely, whether it was from the top of towers or tanks, or by utilizing tripods or lifts. Specialized tools and equipment was utilized to safely reach these areas.

Deliverables: TruePoint delivered over 4,000 individual point clouds, plus TruViews to the client. Our team of in-house engineers created a 3D model of the piping to hand over to the engineering firm to create isometrics of the plant. Our engineers added elbows and valves into their respective locations to create complete pipe runs. TruePoint inspected all files for quality control, to ensure the accurate data for isometric drawings.

Maps were created that show the scan position and point cloud name overtop of the client’s site drawings, allowing the client to easily locate the filename of the scan data. Data was named such that the scanner position filename, point cloud filename, and TruView filenames are all the same. This allows the client to use several tools to view cloud data with consistent naming.

Added Value: The client had never used laser scanning before and although they understood the process, they had many questions about the project. TruePoint Laser Scanning provided the expertise by walking them through the entire process from pre-planning to accurate laser scanning to engineering the final deliverables. This client saved a tremendous amount of time and money. TruePoint was also able to capture ancillary structural information, MEP and piping that might not have been measured by traditional methods.

For a laser scanning provider in Kentucky, contact TruePoint Laser Scanning today at 419-843-SCAN (7226) or email info@truepointscanning.com.

- Client Testimonial:

- “The scan helped tremendously and has saved us quite a bit of time and trouble.”

- Gene Anderson, Mechanical Integrity Engineer