COG Line Gas Pipe Relocation Requires 3D Laser Scanning

Location: Middletown, Ohio

Task: Our client, a leading producer of rolled-steel products for the automotive industry, was relocating a pipe in the COG line (coke oven gas) and requested TruePoint Laser Scanning to capture as built site details and create a LOD 300 Revit 3D model. The client needed one-quarter of their facility (about 330,000 square feet) to be laser scanned and modeled for this project.

TruePoint captured the structure, piping, and equipment for the following areas:

- Pipe rack from the gas holder west to the tar precipitators

- Platform, walkway and pipes on the north side of the tar precipitators

- Pipe rack from the gas holder to the coke battery

- Area on the east end of the coke battery and truck loadout area

- Aisleway under the coke bench

- Exhauster Building main floor on the east end

- Exhauster Building basement on the east end

- Booster gas platform

Challenge: The client needed a structural and MEP layout of the facility as they were relocating a 12" diameter pipe. In order for the client to complete this complex job, they needed a 3D model with a high level of detail. In addition, they needed the point cloud and 3D model aligned to a previous mobilization TruePoint completed in 2020.

Solutions: TruePoint 3D laser scanned the plant with the Leica RTC 360 and the P50 ScanStation. In 184 laser scans, the scan technician captured complete as built data of the facility. TruePoint engineers aligned the new scans and model to previous scans and model in the adjacent and overlapping areas.

Deliverable: The client received an intensity map point cloud (.rcs file), a JetStream Viewer file, and an LOD 300 Revit 3D model. These files were shared via a secure file-sharing platform.

3D Modeling Scope of Work:

- Revit 2019 Software, Design Intent 3D Model

- Two LOD 300 Models were created -- MEP & Architectural/Structural Model

- MEP piping 2” in diameter and above

- Valves, Fittings and Flanges

- MEP Equipment

- Basic structural elements including exposed columns and beams

- Walkway dimensions only, low detail on railings

- Piping connections into the vessels

Added Value:

TruePoint can align point cloud data to existing survey control, site specific control, or existing models if coordinates are received prior to scanning and data processing.

Client Details:

Our client is a leading producer of flat-rolled carbon, stainless and electrical steel products and carbon and stainless tubular products, primarily for automotive exhaust systems. Coke oven gas (COG) or coke gas is a by-product of the coke-making process in iron and steel production. In the coking process, volatile coal material produces COG and carbon intensive coke.

For More Information:

TruePoint has extensive experience 3D laser scanning industrial sites. For 3D laser scanning services in Ohio, contact us today.

- Cleveland | 216-470-7262 | cleveland@truepointscanning.com

- Cincinnati | 513-609-7244 | cincinnati@truepointscanning.com

- Columbus | 614-800-0378 | columbus@truepointscanning.com

- Toledo | 419-843-7226 | toledo@truepointscanning.com

At TruePoint, we possess the passion, resources, experience and capabilities to provide a complete range of 3D laser scanning services.

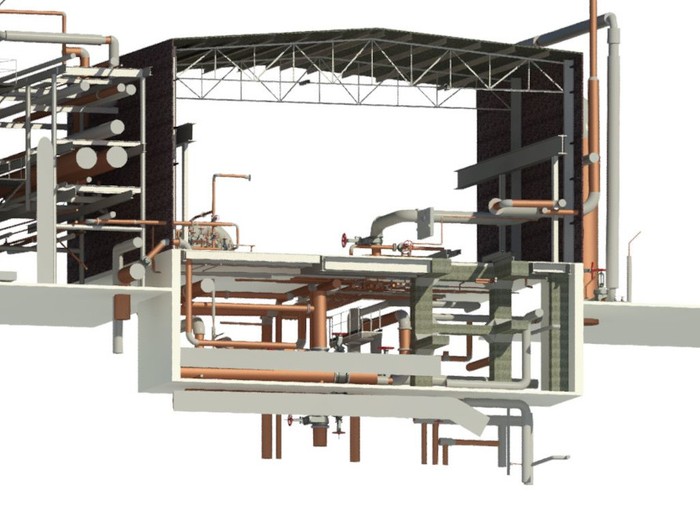

Revit 3D model close up of the plant.

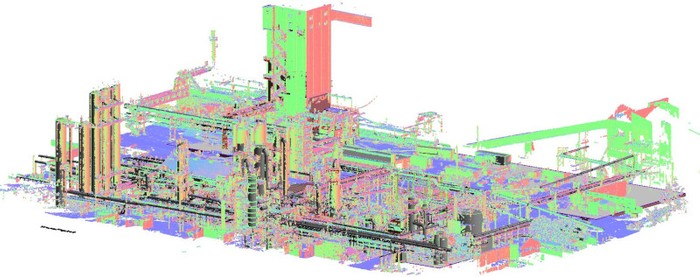

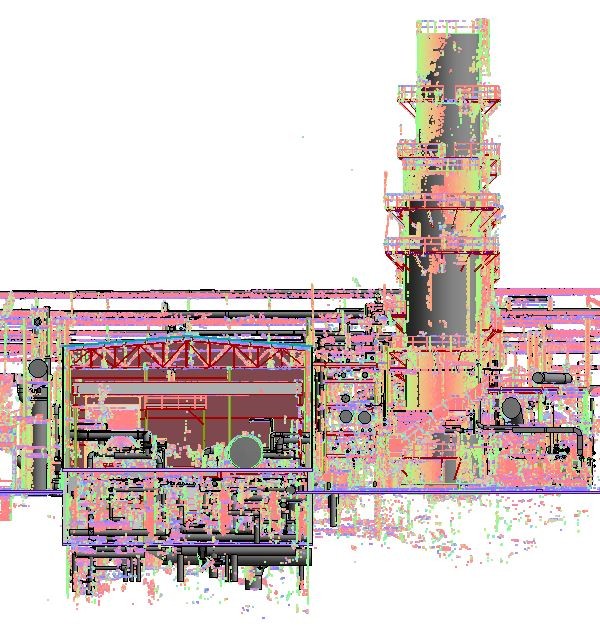

Point cloud overlaid on the 3D model of the plant.

Side view of 3D Revit model.

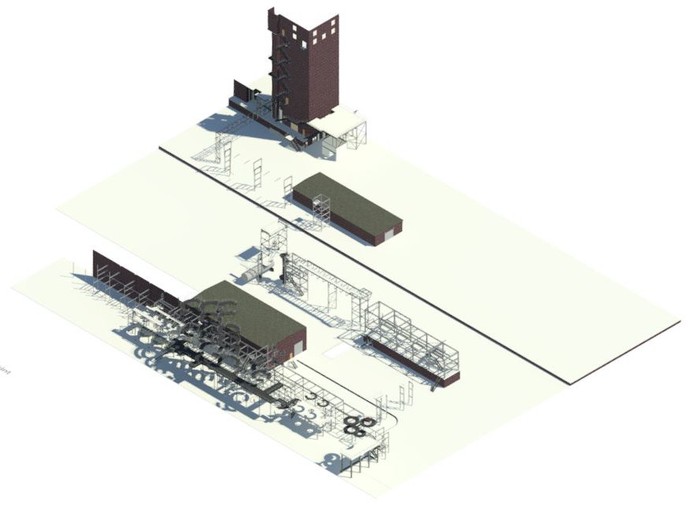

Top-down screen capture of Revit 3D model of the plant.

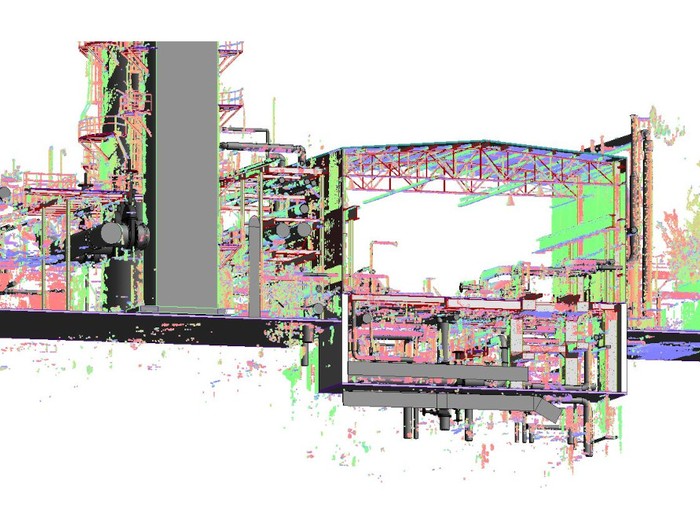

Point cloud overlaid on the side view of the east end of the Exhauster Building's main level and basement.

Side view of 3D Revit model of the east end of the Exhauster Building's main level and basement.

Point cloud overlaid on the model.