TruePoint provided as-built documentation for six airport parking lot structures.

Case Study: As-Built Survey Parking Lot Structures for Prefabrication

Location: Dallas Fort Worth International Airport, Dallas, Texas

Task: TruePoint provided lidar scanning services for six (6) parking lot structures at the Dallas Fort Worth International Airport, ranging from 500 to 2,500 square feet in plan area. The client wanted accurate dimensional information to prefabricate replacement fabric canopies for each of the structures. The target objects of data acquisition were the existing canopy, structural steel, joists, attachment plates, bolts and fasteners. 3D point cloud data was captured and an LOD 200 Revit model was delivered to the client.

Challenge: The client needed accurate information to design replacement fabric panels, including the location of the attachment plates and fasteners. They requested a quick turnaround on this project, TruePoint expedited deliverables within 15 working days of the purchase order.

Solutions: Using an industry-leading, survey-grade Leica laser scanner, technicians from TruePoint’s Texas office captured the existing conditions of the parking lot structures. Dimensions were quickly verified in these high traffic areas of the airport. TruePoint’s team of in-house engineers created 3D models of each structure in AutoCAD format.

Deliverable: TruePoint provided the client with intensity map point cloud files (.RCS files) and AutoCAD 2018 files (.DWG files). The 3D model included basic structural elements, such as exposed structural columns and joists, grade and canopy. With the 3D model, the following details could be used to execute prefabrication - elevations, plan dimensions, radii of rolled elements, plus locations and dimensions of all attachment hardware.

Added Value: An accurate point cloud and 3D model was critical for verifying field dimensions to fabricate replacement canopies. 2D shop drawings can be created with the 3D model building annotation to prefabricate panels. Prefabrication of the panels eased installation, saving resources, time and money.

TruePoint is a highly experienced team of 3D laser scanning professionals who deliver exceptional service, accurate data and custom deliverables to expedite any project. TruePoint can quickly mobilize to your site and provide free project quotes.

For 3D laser scanning services in Dallas Fort Worth call 214-551-6201 or email dallas@truepointscanning.com.

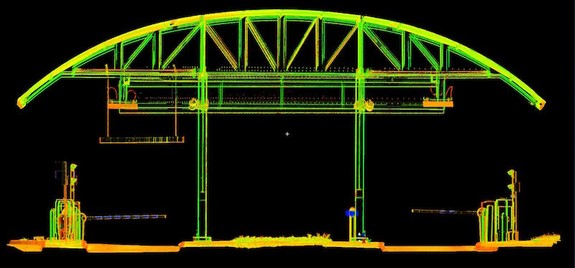

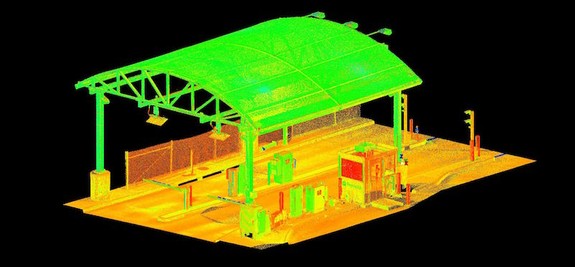

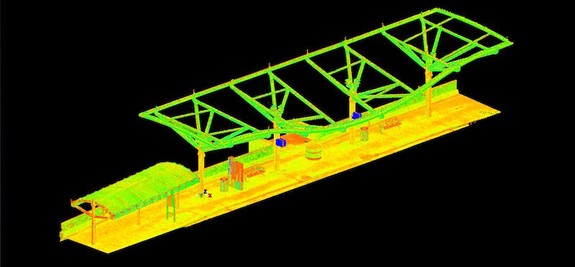

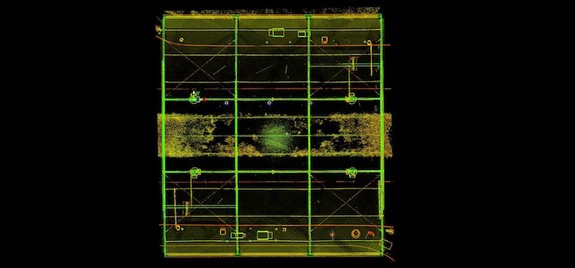

Intensity map point cloud of parking lot structure.

Intensity map point cloud of parking lot structure.

Intensity map point cloud of parking lot structure.

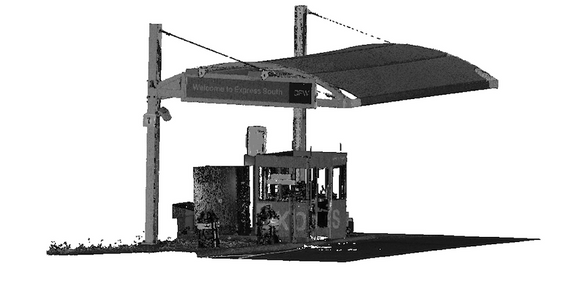

Point cloud data captured on the project site.

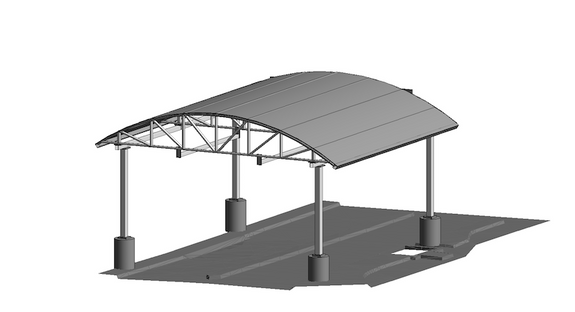

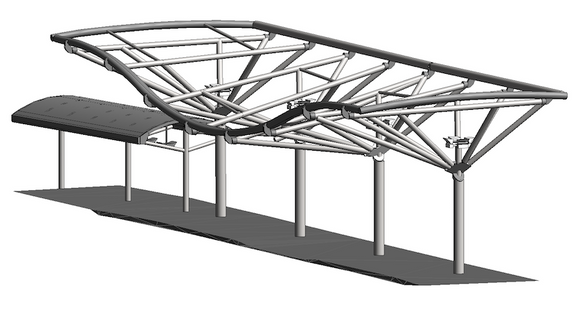

LOD 200 Revit model of commercial parking structure.

The 3D model included basic structural elements, such as exposed structural columns and joists, grade and canopy.

Sample top view of parking lot structure.