Newsletter June 2019

From the Desk of Ryan Hacker...

FOR IMMEDIATE RELEASE

Water Treatment Facilities Under Pressure

With increasing pressures to properly treat and utilize water and wastewater, it’s more important than ever to be resourceful. Our clients are challenged with keeping their facilities running optimally while improving the health, safety and welfare of the public and environment.

Clients are making facility upgrades to:

- Modernize aging equipment and technology.

- Increase capacity for growing populations.

- Improve transport flow to and from the plant.

- Meet state-mandated water quality goals.

- Improve energy-efficiency and reduce energy costs.

- Protect local bodies of water and ecosystems.

Without the right integration of process and purification technologies, facilities risk a host of problems that affect the quality of the water and the life of the equipment.

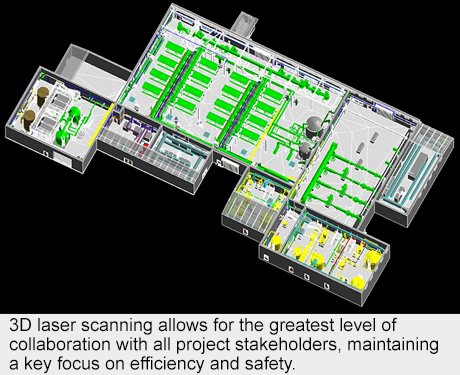

3D Laser Scanning Aids Renovations

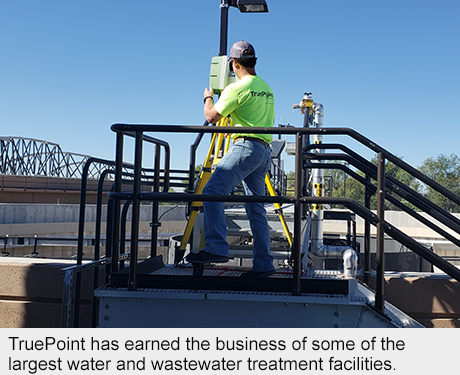

TruePoint has earned the business of some of the largest water and wastewater treatment facilities. As infrastructure upgrades are made, clients look to TruePoint to 3D laser scan their facility and document existing conditions. This expedites planning, design, procurement, environmental review and construction. Clients are able to complete projects on time, on budget, and with minimal modifications.

TruePoint can quickly mobilize to your site and provide free project quotes. Call us today at 419-843-7226, or email info@truepointscanning.com.

Featured Case Study

Laser Scanning 120 MGD Water Treatment Facility

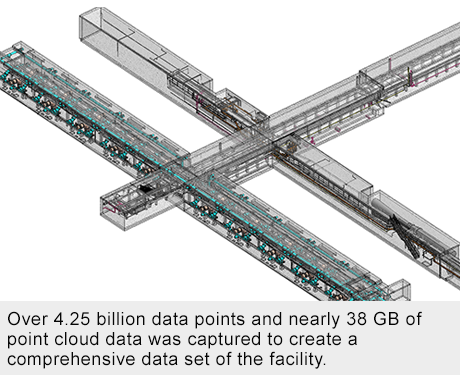

This Water Treatment Facility was built in 1941 and has undergone many additions and changes to the plant since the initial construction. Water system upgrades and improvements are constantly being made to keep the water system functioning at peak performance levels. Given the age of the water plant and ongoing updates to the facility over the decades, the client had no accurate as-built drawings of the facility.

The task was to laser scan the sub-level of a 120 MGD treatment area capturing all structural, mechanical, electrical and plumbing features, equipment and piping down to ½ inch in diameter.

Comic Relief

Testimonial

“We installed all the prefabrication that was based off your scans and model and just wanted to pass down that everything worked out well.”

K. Wallace, Mechanical Integration/Mechanical Engineer