Newsletter December 2018

From the Desk of Ryan Hacker...

FOR IMMEDIATE RELEASE

Thank You From All of Us at TruePoint Laser Scanning

I am truly grateful for your business and the trust you’ve placed in TruePoint Laser Scanning. You are important to us. Our regional managers and scan technicians work tirelessly in the field to capture and register data. Our engineers integrate the latest as-built modeling technologies to increase the productivity and accuracy of their scan-to-finish workflows. I believe 3D laser scan data is more important than ever before, as it provides critical information to diverse technical disciplines. We are more excited than ever about the future.

With appreciation at the holidays and the New Year,

Ryan Hacker

2018 Milestone Projects

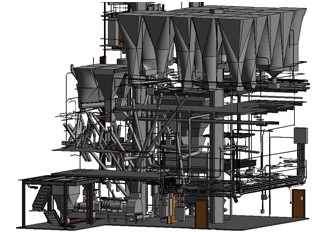

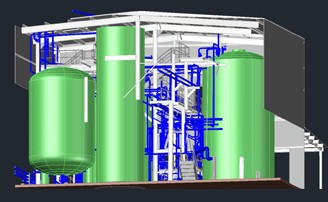

Manufacturing Process Tower and Extruder Room

Lebanon, Tennessee

TruePoint 3D laser scanned a process tower and extruder room for a manufacturing facility in Tennessee. Our in-house CAD designer delivered an LOD 300 Revit model detailing the structural layout of tower and extruder room; the MEP dimensions and connection points. The client will be using the 3D model to precisely plan their steps for the removal of existing equipment, as well as, knowing the best options for the installation of new equipment and piping.

Andy Foshee - Southeast Regional Manager

“The client's main objective in using laser scanning was to help them understand the as-is conditions of both the process tower and extruder room prior to removal and installation of equipment.”

Rick Rill - CAD Designer

“We used multiple software programs to create two separate models for the client, one mechanical and one structural.”

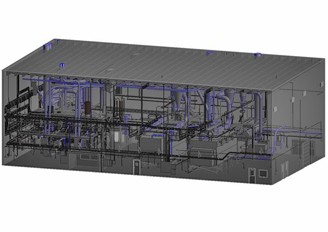

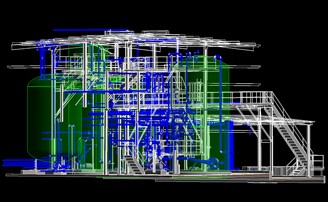

Water Treatment Facility

Philadelphia, Pennsylvania

Water treatment facilities and pump stations present unique obstacles for field measurement and analysis. TruePoint 3D laser scanned the interior area of this water treatment facility and delivered a 3D model with complete structural and MEP features.

Nate Baker - Northeast Regional Manager

“In three days onsite, TruePoint was able to capture the facility's complex piping and equipment with very minimal shadowing, giving our modeling team the information they required to create a highly-detailed 3D as-built model.”

Aaron Hunt - PE, Technical Manager

“Custom-built advanced Revit families were created for all the varying features so that each layer could be selected or de-selected depending on which portion of the model was being analyzed by the client.”

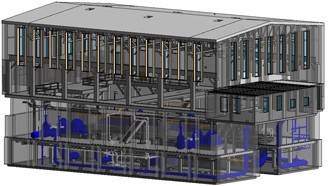

Chemical Reactor

Celine, Texas

TruePoint 3D laser scanned a chemical reactor to capture the piping, structural steel, flanges, valves, stairs, and cooling tower. The client received a LOD 350 Revit model, giving them the ability to design modifications to the reactor from their office with no field visits.

David Sauceda - Texas Regional Manager

“Planning within a virtual environment eliminates clashes and delays on project timelines. Our clients can go into projects with a plan of action and execute it efficiently.”

Michelle Colella - Chemical Engineer, CAD Technician

“A Revit model gives the client an easy to use, dimensionally accurate baseline data set so that they can measure and plan equipment installation before they mobilize to the field work phase.”

Comic Relief

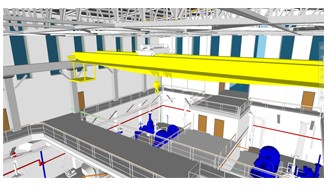

Testimonial

“The point cloud model worked out tremendously well. This was almost the perfect project to use it on due to the various intricacies of the building layout and large differences from floor to floor. Documenting the existing building conditions the usual way would have been extremely difficult.”

-N. Pellizzari, Architecture and Planning Professional