Case Study: Laser Scanning of a Water Purification System

Location: Malta, New York

Task: To scan the three main tanks of a water purification system in order to capture information regarding their exact sizes, locations, and spaces, as well as all of the structural and MEP features associated with the existing units. The facility was going through an expansion which would increase the water purification capacity, so the engineers needed to understand how the existing systems were designed and how they fit in the current space in order to determine where and how the new systems could be installed. Since the available space was limited and the systems had to be designed a particular way, clash detection—locating existing obstructions—and accurate pre-fabrication for tying the new systems in with the existing piping and tanks was crucial.

Challenge: As with many processing facilities, the space was congested and complex. The engineering firm that designed and installed the original units was no longer involved, and the current firm hired for the new systems only had outdated drawings. An additional challenge was that the units were tall, making accurate measurements of the existing systems difficult to obtain through traditional field measurement techniques.

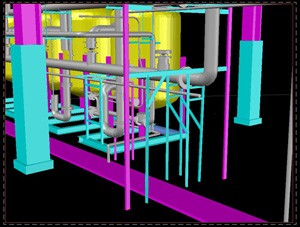

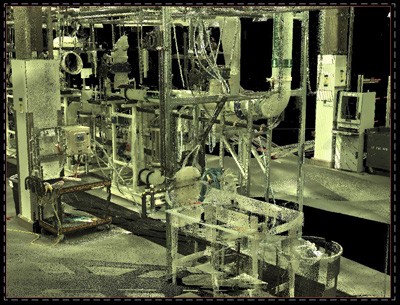

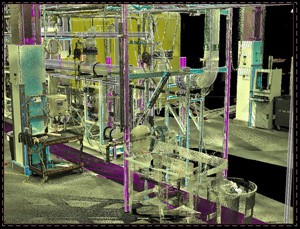

Solutions: All of the complex issues of measurements and design were addressed by using 3D laser scanning to capture the as-is conditions of the existing tank and pipe systems. This gave the client the necessary information for designing and building the new units. This also allowed the client to determine the amount of space necessary for the new systems, how they would fit in the space and what potential clashes existed. Lastly, since the new units were built off-site, it was important that everything fit correctly the first time, in order to both save time and reduce any extra cost that would be associated with re-designing or re-building the new units.

Deliverable: TruePoint provided the client with 3D CAD models (.dwg file format) of the three specific tank areas.

Added Value: By using laser scanning, the client not only received a much more accurate model, but the client also saved time and money by not having to send in their own team to take field measurements, which would have included renting lifts and hiring lift operators in order to gain access to the key areas.

If you have a water purification system that requires complete and accurate as-built drawings or models, contact TruePoint Laser Scanning to discuss your specific needs at 703-835-5226 or washingtondc@truepointscanning.com.

3D Model of a Water Purification System in CAD Format

Point Cloud of a Water Purification System

Point Cloud and Model Overlay