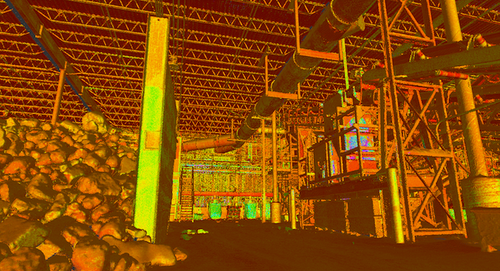

Intensity map point cloud of scrap pile and pipe run located in the facility.

Case Study: Laser Scan Technology Delivers Point Cloud Data for a Recycling Mill

- “Being able to verify as-built dimensions before parts are fabricated and delivered on site is crucial for completing modifications on time and within budget. The data we captured allowed our client to do just that, with confidence."

- - Karl Hofmeister - Scan Technician

Location: Friendly, West Virginia

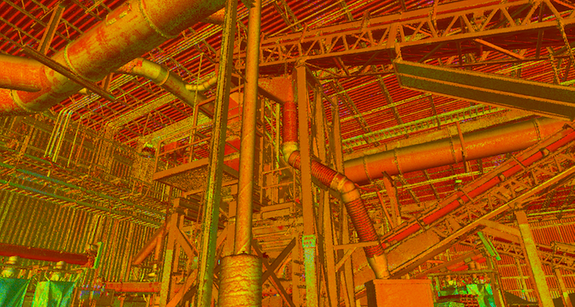

Task: TruePoint Laser Scanning was asked to scan approximately 10,000 sq. ft. in a recycling mill where various processes take place to melt down scrap metal and repurpose it. The scans would include milling equipment, pipe runs, and exhaust hoods on both the interior and exterior of the main building.

Challenge: The client was replacing various components of the existing equipment and accompanying piping systems located in the facility. Many of the features being replaced were located 15 to 20 feet above the ground and were comprised of shapes that would be difficult to measure by hand.

Solutions: A state-of-the-art RTC 360 scanner was used to capture 59 scans of the current equipment at a rate of 2 million measurements per second. Through the use of 3D laser scanning technology, the client saved considerable time versus taking measurements by hand. The scan data also more confidently determines that the planned equipment would fit properly in the intended installation area of the plant.

Deliverable: With a point cloud (a large collection of points acquired by 3D laser scanners or other technologies) TruePoint professionals can create 3D representations of existing structures. In this case, an Intensity Map Point Cloud was created for the client to provide real-world context for referencing where the new equipment would be positioned within the existing space.

Added Value: By receiving a 3D as-built depiction of the space under consideration, the client could confidently design and implement the needed mechanical components in the existing facility while avoiding guesswork and costly installation surprises.

TruePoint is a highly experienced team of 3D laser scanning professionals who deliver exceptional service, accurate data, and custom deliverables to expedite your project. TruePoint can quickly mobilize to your site and provide free project estimates.

For 3D laser scanning services in West Virginia, call 513-609-7244 or email westvirginia@truepointscanning.com.

Many of the features being replaced were located 15 to 20 feet above the ground and were comprised of shapes that would be difficult to measure by hand.