Ethanol Plant Upgrades to Increase Efficiency and Lower Emissions

“We were extremely impressed with GPRS in your timeliness on responding to our request, to having a crew on site to complete the scan, and in your communication with us through the process. This was the first time we have used GPRS modeling services, and the 3D model your team created was outstanding. We were very impressed with the level of detail and quality of the model, the speed in which your team was able to create it, and all aspects of communication during the process.” TLF Engineers’ Senior Project Engineer Seth A.R. Gressley, P.E.

Location: Clymers, Indiana

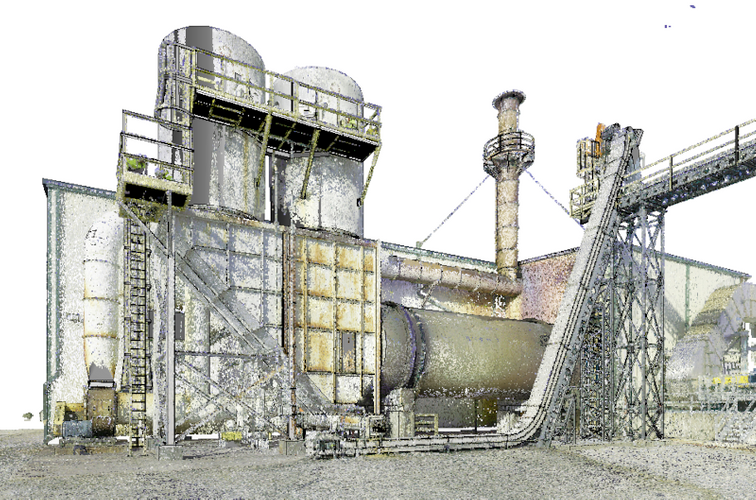

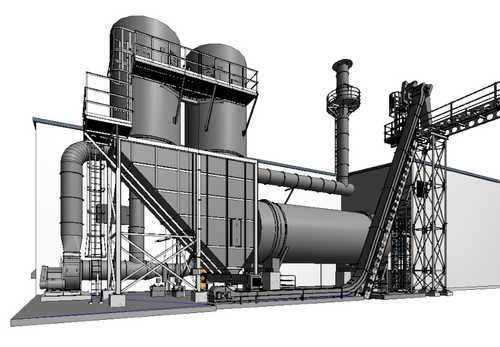

Task: GPRS was hired by TLF Engineers to 3D laser scan the exterior cooler area at the southeast corner of The Andersons’ Indiana Ethanol Plant and create a 3D BIM model for process improvements.

Project Application: 3D laser scanning collects accurate agricultural as-built data safely from the ground, delivering precise site layout and dimensions for design planning and analysis.

Problem:

The Andersons’ planned to make process improvements over the next five years to improve operational efficiency and lower plant emissions

- TLF Engineers needed up-to date as-builts of the plant infrastructure to design upgrades to equipment and production lines

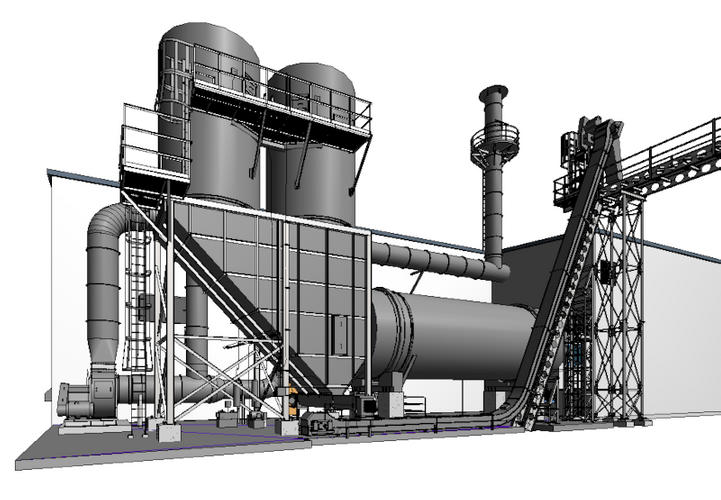

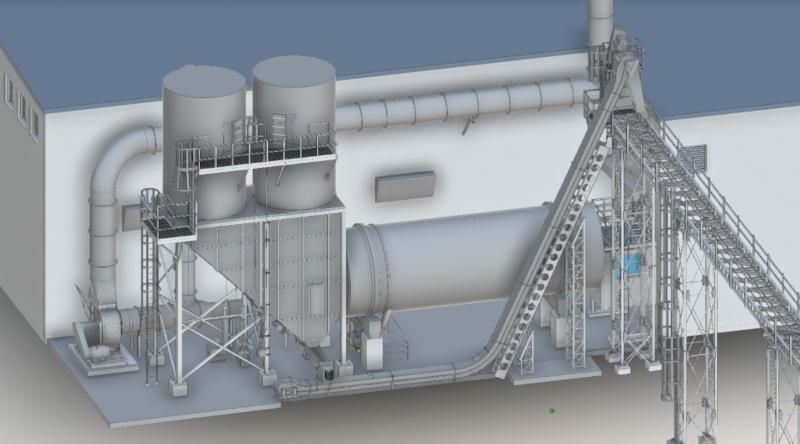

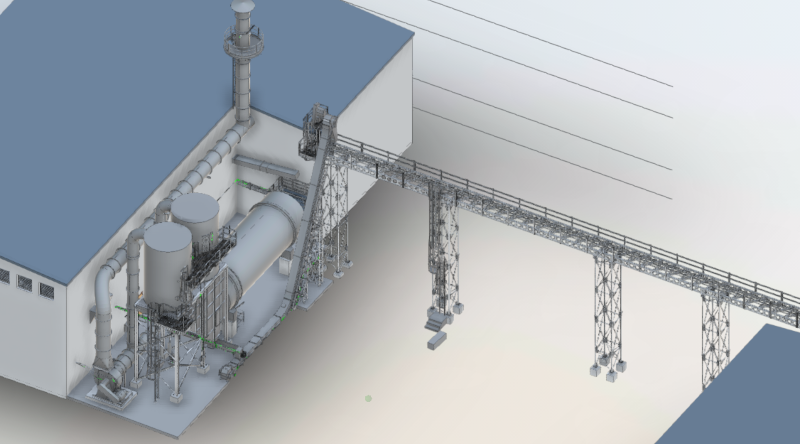

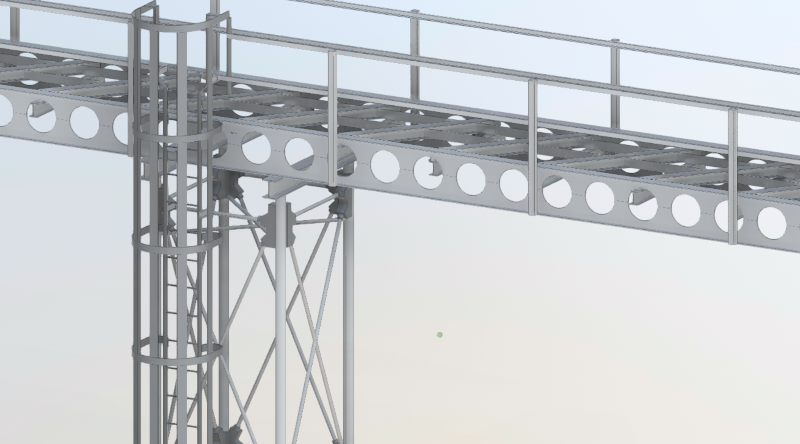

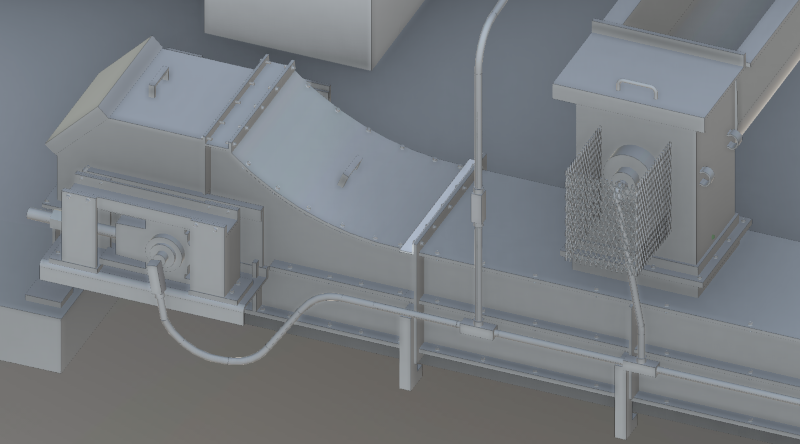

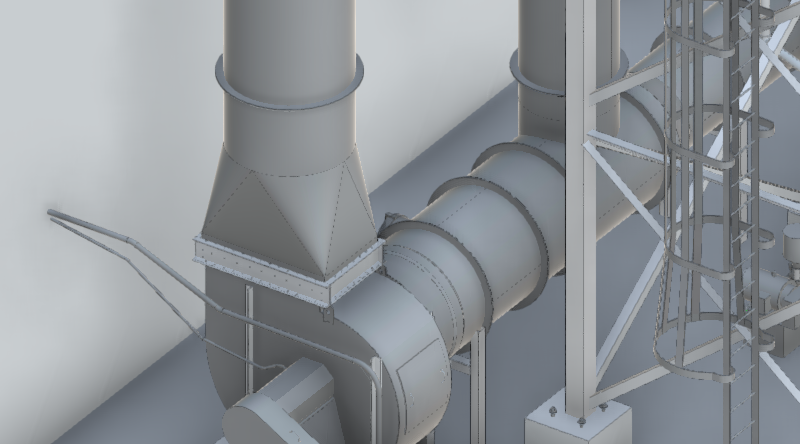

- Precise details were required for a 2,500 sq. ft. area, including the existing cooler, drop box, dust collectors, platforms, cooler, stack, and ductwork

Solution:

3D laser scanning captured a colorized point cloud with 2-4mm accuracy and HDR images in less than 3 minutes per scan location

The point cloud was used to develop a 3D BIM model at a very high level of detail with precise architectural, structural, and MEP features

TruView 360° photographs provided a virtual site tour, allowing the client to take basic dimensions, estimate clearances, and markup the project site.

Benefits:

Comprehensive data of existing structure and equipment was crucial to plan process improvements and equipment optimization

- With a detailed 3D BIM model, the engineering team was able to virtually design the facility layout, retrofit equipment and optimize workflow

- Updates improved ethanol yield and quality, increased production efficiency, and lowered plant emissions

For 3D laser scanning services in Indiana, contact:

- Fort Wayne

- Indianapolis

Laser Scanning Images for Ethanol Plant Upgrades