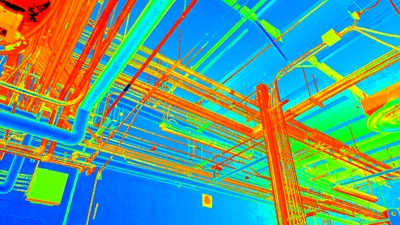

Raw intensity map data of above ceiling piping

Case Study: As-Built Las Vegas Process Facility

Location: Las Vegas, Nevada

Task: To capture existing piping and conduit for an equipment upgrade project. The facility had many active and abandoned lines, neither of which were identified. The scanning was to help capture the piping in order to help the client identify which lines were active and which were no longer in use. The client also needed to tie in to some of the existing lines, rendering accurate as-builts critical to the project.

Challenge: The project took place in an active facility and operations could not be halted in order to create as-builts. Additionally, the majority of piping to be captured was located above a drop ceiling in an active process room. Accurately documenting dark and congested above-ceiling areas can be difficult using manual methods, but adding to the complexity was the fact that this was an active production facility. Therefore, only one ceiling tile could be removed at a time, and stopping the product lines was not an option, which would make the use of man lifts or other means difficult.

Solutions: TruePoint was able to scan all the areas in the production room, above the ceiling tiles, using only a 12’ tripod and a ladder. Only one tile needed to be removed per location, and the scanner could be set at the proper height to capture the piping above, with the equipment below. Using our P-20 scanner, each scan took only 2-3 minutes to capture millions of data points in an area that was otherwise hard to access or see due to the lack of light above the ceiling.

Deliverables: The deliverable was the raw scan data (point cloud). Since the laser does not require light to capture data, an intensity map point cloud was created for the above-ceiling scans. In locations where there was adequate lighting elsewhere in the facility, we utilized the built-in camera on the scanner to deliver a colorized point cloud. The client will use this data to create a 2D or 3D model of the existing conditions.

Added Value: The customer had little to no access to the areas above the ceiling tiles and needed to create up-to-date drawings of the existing piping and conduit. Given the circumstances of this facility, this would have been a difficult task to do without the use of laser scanning. TruePoint was able to scan all of the areas in two days and provide the client with detailed information on the piping in the areas they needed information on. When data is needed for areas difficult to access or locations that may be too dark to see in, TruePoint has a fleet of scanners to help provide you with the information you need.

Laser scanning is currently one of the fastest ways of gathering highly accurate field measurements. The amount of time TruePoint spends on-site gathering measurements can be minimal compared to traditional field measuring. By saving time in this way, the client is better able to focus their time in a more productive manner.

If you are in the Denver area or on the West Coast and need updated as-builts, historical documentation, construction verification, or any other 3D laser scan applications, please email or call Dave Schaff at denver@truepointscanning.com or 720-618-1029.

Also, if you are interested in hearing more about TruePoint and the services we offer, please reach out and we will provide a free lunch-and-learn presentation at your office.

Colorized point cloud data (utilizes on-board camera and requires adequate lighting)

Above-ceiling laser scanning utilizing extended tripod