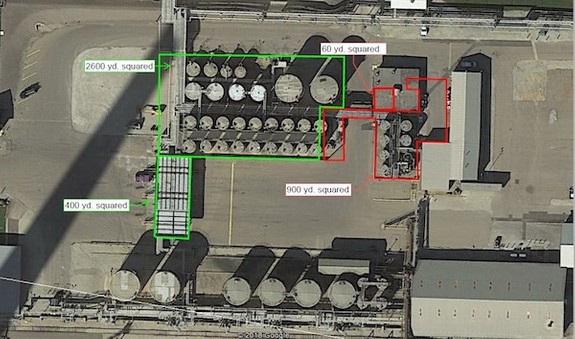

3D laser scans were taken in this area of the site to depict a main pipe rack entering the tank farm.

Case Study: 3D Scanning Upgrades a Remote Facility

“Retrofitting upgrades into an existing facility is always a challenge. Having point cloud data saved this client countless hours of traveling to the site and eliminated the guesswork. TruePoint streamlined the process of gathering the necessary field information." - Karl Hofmeister, Project Manager

Location: Cincinnati, Ohio

Task: Located in an asphalt refinery production facility, TruePoint was tasked with laser scanning approximately 45,000 square feet of the asphalt terminal. The area to be scanned consisted of various tank farms, production areas, overhead pipe racks, mill room and a loading station. The client required a 3-dimensional as-built representation of specific areas within the facility to plan for updates and enhancements within the space.

Challenge: Modifications to the existing facility meant that company engineers must design new equipment that could connect and operate cohesively within the current surroundings. This particular space contained an abundance of overhead pipe racks that would need to be rerouted to various locations throughout the facility. All updates would need to be accomplished while leaving the existing equipment as undisturbed as possible. With access only to 2-dimesional drawings the project engineer sought out a 3-dimesional alternative to help his team accurately and efficiently plan their project.

Solutions: Using the Leica ScanStation P40 and RTC360 laser scanners, TruePoint obtained 237 colorized scans of all the pertinent areas in just a few days. After the TruePoint team registered the data, point cloud files were delivered to the client on an external hard drive for the project team planning.

Deliverable: TruePoint laser scanning professionals delivered a fully registered, colorized point cloud, along with JetStream Viewer files to the client. A colorized .pts file was also created from the Leica Cyclone to aid with planned site renovations to the asphalt terminal.

Added Value: This facility was one of many that the client operates several hours away from their headquarters. With point cloud data of the site, the project engineer and his team could save countless days by eliminating roundtrip drives to the actual site. Precise measurements could be made in seconds with the point cloud, eliminating the need for hours of cumbersome and time-consuming manual measuring. With the unquestionable accuracy of 3D technology, the client can be assured that designs made within the point cloud will be implemented successfully in reality.

TruePoint has extensive experience 3D laser scanning refinery and production facilities. We are a dedicated team of 3D laser scanning professionals who deliver exceptional service, accurate data, and custom deliverables to expedite your project. TruePoint can quickly mobilize to your site and provide free 3D building scanner estimates.

For 3D laser scanning services near me, call 513-609-7244 or email cincinnati@truepointscanning.com.

The project scope was to laser scan approximately 45,000 square feet of an asphalt terminal.

3D laser scanning the area where the loading terminal protrudes from the rest of the tank farm.

Leica RTC360 laser scanner as it captures the main pipe rack connecting the production area to the main tank farm.

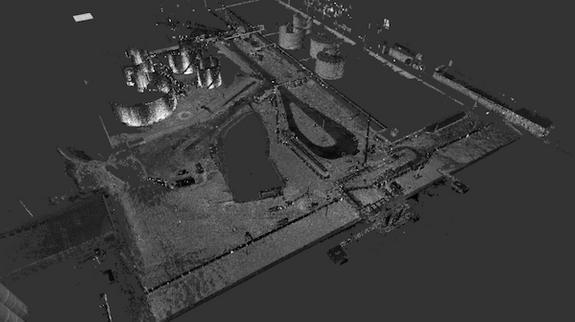

Point cloud screenshot of the asphalt refinery production facility.

Point cloud screenshot of pipe runs to the asphalt storage tank.