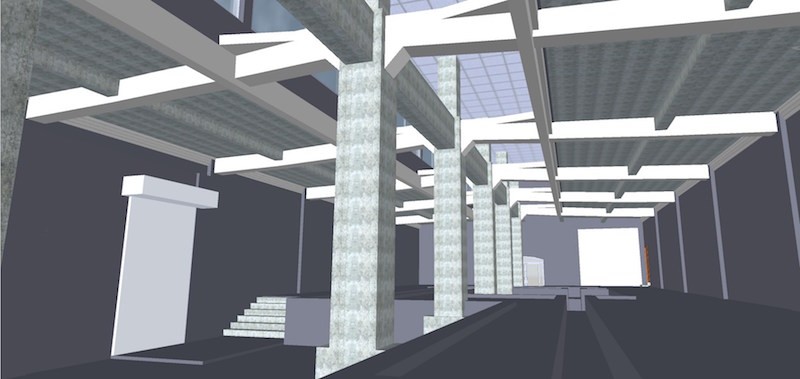

Open end view of the 3D model.

Case Study: 3D Model Expedites a Warehouse Retrofit

- “This industrial space contained many unique building features that posed challenges for the renovation. 3D laser scanning saved time, money and eliminated weeks of costly guesswork.”

- - Zach Jones, Great Lakes Regional Manager

Location: Cleveland, Ohio

Task: TruePoint was tasked with capturing and creating an LOD 200 Revit model of the interior of an existing industrial space. The one-story building was soon to be converted into an additional spray booth and robotic system at a manufacturer of liquid coatings. The timeline of the project required expedited 3d laser scanning services for an exceptionally quick project turnaround.

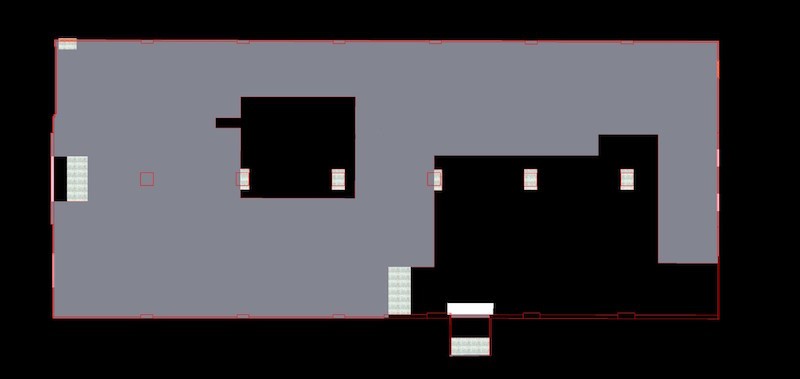

Challenge: Our client, an industrial design consultant, was hired to plan the interior transformation of the existing warehouse into a new robotic spray booth. The area contained a variety of pits, channels, columns, stairs, piping, etc., in which to retrofit the new functional space and machinery. The client needed an accurate, as-built survey in order to design the new building components and modifications in a way that they would fit properly.

Solutions: TruePoint was able to successfully reality capture every aspect of the 6500 sq. ft. interior. The 3D BIM model allowed the client to accurately and confidently fulfill their task of designing the spray booth and robotic components in and around the existing space. The model removed all concerns that the new machinery would not properly fit the space when it was time for installation.

Deliverable: Using a Leica RTC360 3D Laser Scanner, 45 laser scans were taken to accurately survey the industrial space. The client received an intensity map point cloud, Jetstream viewer files, and an LOD 200 3D Model in Autodesk Inventor.

Added Value: Significant time, effort and resources were saved by having TruePoint reality capture and model the space onsite. While hand measurement may have been possible, that process would have been costly and labor intensive in order to achieve the level of accuracy required for the project. In addition, a substantial amount of time and budget were saved by being able to design the new equipment directly inside of the model we produced, rather than guessing whether or not the designed equipment will properly fit the space.

TruePoint is a highly experienced team of 3D laser scanning professionals who deliver exceptional service, accurate data, 3D robotic imaging, and custom deliverables to expedite your project. TruePoint can quickly mobilize to your site and provide free project estimates.

For 3D laser scanning services in Cleveland, Ohio, call 216-470-7262 or email cleveland@truepointscanning.com.

A second view of the LOD 200 Revit model.

Overall image of the space, noting the variety of terrain and unique features.

The Leica RTC360 laser scanner capturing various unique features of the space.

Plan view of the space from the top down.

Open end view of the 3D model.

The Leica RTC360 laser scanner capturing various features of the space including different elevations.