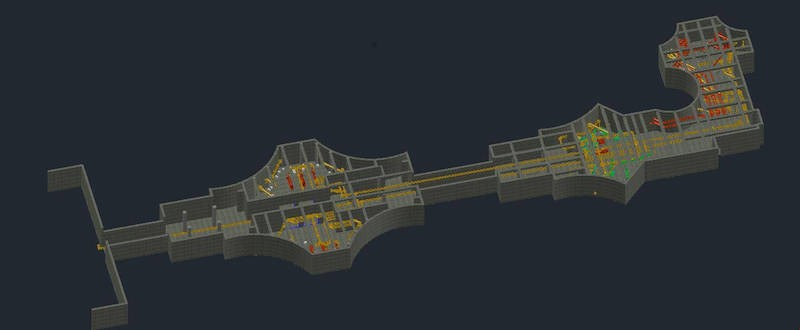

Image showing the elevation plan in Leica Cyclone.

Case Study: 3D Laser Scanning a Wastewater Treatment Plant

Location: Columbus, Ohio

Task: 3D laser scan a 400-foot interior tunnel and adjacent digester tank pumps and piping for a Wastewater Treatment Plant in Columbus, Ohio. TruePoint Laser Scanning captured all structural features such as walls, floors, ceiling, columns and beams; a footprint of mechanical, electrical and plumbing equipment; and piping ½” in diameter and greater.

Challenge: The area was dense with piping and traditional means of surveying would be costly and time consuming. Due to multiple layers of piping it would have been challenging to measure the area without the use of ladders or scaffolding.

Solutions: TruePoint’s scan technician communicated directly with the client to determine the best possible method for laser scanning the 400-foot tunnel and exterior of the digester tanks. Due to the density of piping and deliverable requested, the technician determined that intensity map laser scanning was the best option for the client, as more scans could be completed within the time frame and budget. The technician performed over 150 individual setups to ensure laser scan data was more complete. TruePoint expedited the data collection process for this client by capturing all visible features in less than one week on site. Dense overhead piping was captured safely from the ground without ladders or scaffolding.

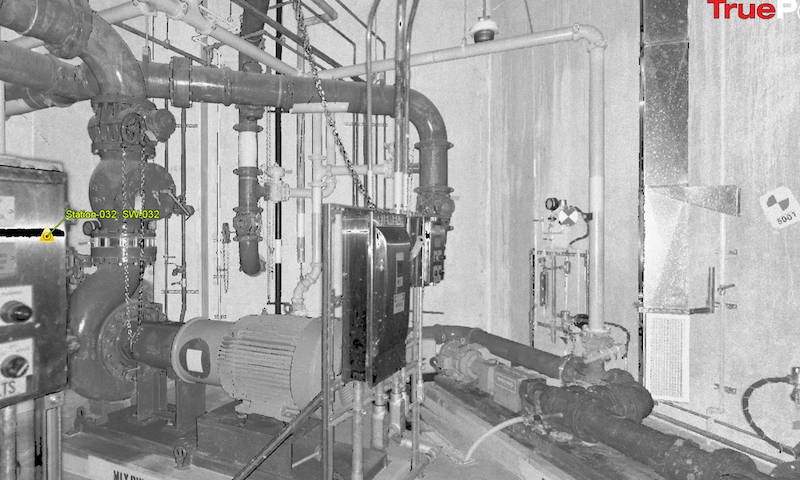

Deliverables: The client received Autodesk Recap files (.rcs file format) of the laser scan data as well as black and white TruViews. TruViews are 360 degree 3D photographs overlaid on top of the point cloud that allow the user to look around from the scanner’s perspective and even take measurements directly from the photo.

Added Value: TruePoint provided detailed benchmark locations so that the client could have the data tied to survey control after completion of the laser scan. TruePoint regularly communicated updates to the client on scheduling, timeline and completion of the project.

For laser scanning of water and wastewater treatment facilities, contact TruePoint Laser Scanning at columbus@truepointscanning.com or 614-800-0378.

3D model of 400-foot tunnel and adjacent digester tanks.

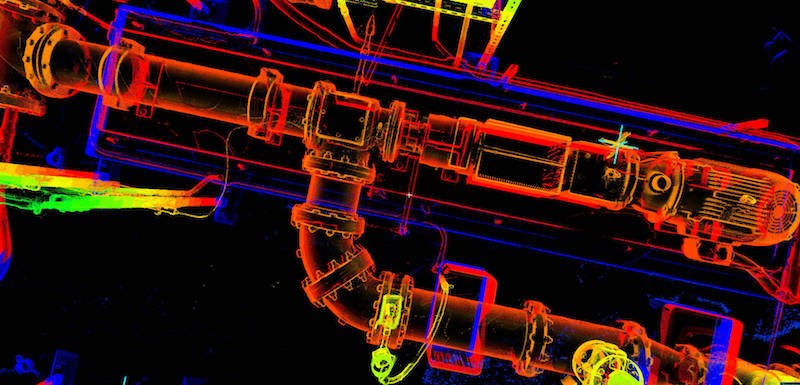

Due to the density of piping, the technician determined that intensity map laser scanning was the best option in order to capture more scans in the allotted amount of time.

TruePoint captured the dense overhead piping safely from the ground without ladders or scaffolding.

TruView of the wastewater treatment facility.

One of TruePoint’s Leica P40 scanners laser surveying all of the visible structural features, MEP equipment and piping down to ½” diameter.

TruView of digester tank in the wastewater treatment facility.

Leica Cyclone screen capture of valves and piping in the wastewater treatment facility.