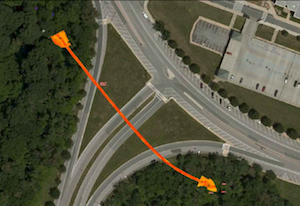

Laser Scanning the End of the Culvert

Case Study: 3D Laser Scanning of Metal Culvert Pipe

Location: Baltimore, Maryland

Task: To utilize 3D Laser scanning to laser scan an existing corrugated metal culvert pipe.

Challenge: The client needed to fit a custom-sized liner to the interior of the metal pipe but because of settlement issues, rusting of the bottom of the pipe, deformation, and overall environmental damage sustained to the pipe, traditional methods would have made measuring the pipe difficult. Additionally, the pipe was almost completely dark on the interior, making it even more difficult to measure by traditional survey methods. Laser scanning does not require light to capture data, though, so the entire pipe could be captured through 3D laser scanning.

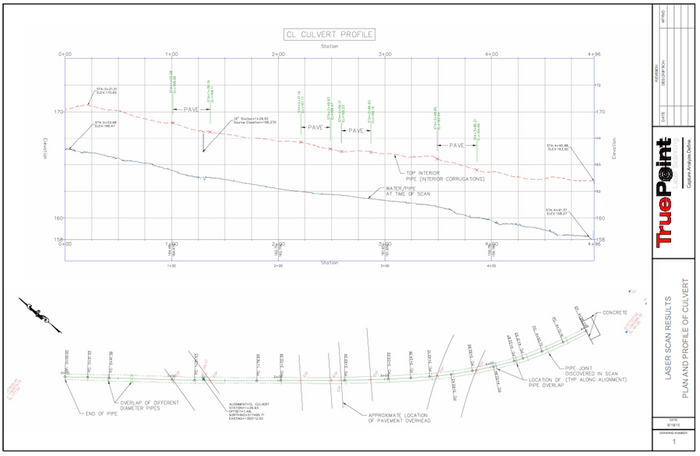

Solutions: By utilizing 3D Laser Scanning, the entire length of the pipe was captured within one day. TruePoint was able to register the data to existing survey control for the client’s use and generate an accurate plan and profile view(s) of the culvert.

Deliverables: TruePoint generated AutoCAD Civil 3D Models, Navisworks files, AutoCAD files, and point cloud files in rcs format.

Added Value: TruePoint was able to mobilize within days of notification and scan the entirety of the culvert in one day and then began generating deliverables immediately upon completion of the scan. Information would have otherwise been difficult to measure due to lighting issues and the line of sight within the culvert. However, 3D Laser scanning is not dependent on light to capture data points and has a long range with which to capture distant features that might otherwise be missed.

For other 3D laser scanning needs associated with culverts and Civil Engineering site projects, please contact TruePoint Laser Scanning at 419-843-7226.

Point Cloud Data Overlaid and Aligned on AutoCAD Maps

View from Inside the Culvert

2D Drawing Showing Culvert Pipe Profile and Elevation