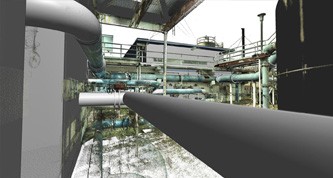

3D Model of piping with point cloud overlay used for clash detection of complex area

Case Study: 3D Laser Scanning of a Water Treatment Facility

Location: Palm Bay, Florida

Task: To laser scan a series of above ground pipes connecting various solids tanks and filter structures at a water treatment facility. The client needed the scan to capture the basic exterior footprint of the surrounding buildings and structures in the scan area. The scan also needed to include the inside of the water tower/tank, capturing the 12-inch fill line to the top of the tank, as well as the point where it exits the tower.

Challenge: Though the client has some 2D drawings of the pipe runs, the existing drawings do not show accurate detail of critical, complex areas for potential clashes, as the pipes change elevations and weave in and around other pipes and in and out of various structures. In addition, the client was interested in having accurate measurements and locations of the piping, as well as the connection points of the water fill piping inside the tower, which, due to the height of the water tower, are difficult to get to. The use of 3D laser scanning, though, makes acquiring the information much easier.

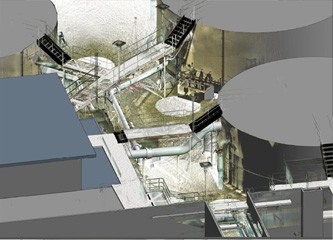

Solutions: Utilizing 3D laser scanning, TruePoint was able to take several scans from different angles, with each scan capturing measureable points of data. By combining these scans into a single point cloud of data, the client was able to receive an as-is 3D model that can be used to insert proposed changes and look for clashes, as well as plan methods to mount and support the pipes. TruePoint Laser Scanning is also able to capture detailed information on higher elevations safely from the ground, eliminating the need for man lifts or repelling equipment.

Deliverable: The client was interested in receiving the point cloud gathered from the scans in a file format that could be imported into their Autodesk AutoCAD 2013 software. In addition, an AutoCAD 2013 3D model was created of the piping and the footprint of the surrounding buildings and tanks in the scan area. Lastly, the client was provided with TruViews, which are 3D photographs from each scan location’s perspective overlaid on top of point cloud data so that a user can look up/down/left/right and even zoom in/out and take basic measurements directly from the photographs.

Added Value: The client’s project is multi-phased in order to continue operating while replacing certain pipes and valves. Using manual field measuring techniques, the client was planning on capturing this information in multiple phases as well; however, by utilizing 3D laser scanning, we were able to capture data on the areas of concern in a single day of scanning at the site. Not only does this reduce cost by eliminating multiple mobilizations, but this will provide the client with all of the data needed for the project ahead of time, making planning and scheduling efforts much more productive and reducing future change orders.

If you have a water treatment facility that requires complete and accurate as-built drawings or models, contact TruePoint Laser Scanning to discuss your specific needs at 407-558-9716 or orlando@truepointscanning.com.

Modeled pipes overlaid on top of colorized point cloud data in Revit 2014

Overview of model and point cloud showing MEP features, building footprints, tanks and walkways captured using 3D Laser Scanning