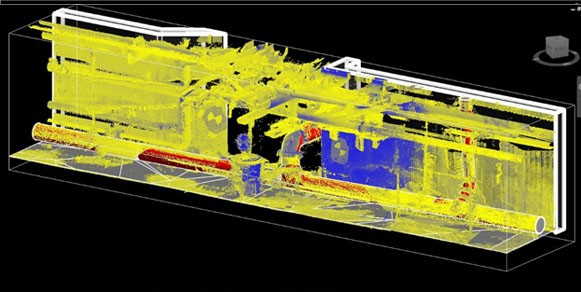

Elevation details of a section of tunnel with the point cloud showing the fire water main

Case Study: 3D Laser Scanning and As-Builts Created for Interior Utility Tunnels

Location: Ann Arbor, Michigan

Task: To laser scan the interior of utility tunnels underneath a college dorm in order to obtain the basic tunnel structure, including walls, ceiling, visible concrete beams, and floor, but focusing, also, on capturing the water main that supplies the fire protection system.

Challenge: Due to the extremely tight renovation schedule mandating that the dorm only be out of operation for one school year, the client was in need of an accurate as-built model of the space to be used in the pre-design phase of the project. In order to meet the aggressive schedule, the client needed to pre-fabricate and build all of the new piping, racks, and systems so that they could be installed as soon as construction begins, thereby only requiring the connection of the separate units when they are put in place in the tunnel. In addition to needing highly accurate and detailed information in order to design the new equipment, these utility tunnels have varying ceiling heights and widths, as well as areas of high congestion where numerous pipes, valves, and support structure converge, all of which would make it difficult, tedious, and time-consuming to take accurate field measurements by traditional methods.

Solutions: By using 3D laser scanning to capture the tunnel structure and respective MEP features, the client has the information necessary to accurately and confidently build their new systems before construction even begins. Having these systems ready to go when construction begins allows the client to reduce the construction schedule and installation time significantly. And by limiting the construction life cycle to one school season, the university will save millions of dollars since revenue lost will be reduced dramatically by not having to close the dorm for multiple school years.

Deliverables: A point cloud file was provided as an indexed point cloud file (.pcg file format), ready to import into the client’s AutoDesk 2014 products. Also provided to the client was a Revit 2014 model of the basic interior structure of the tunnel walls and ceiling surfaces and a mesh of the floor surface. The model also shows the visible concrete beams and columns as well as the fire main pipe run. TruePoint also provided black-and-white TruViews that utilized the point cloud data in order to show 360 degree views from the scanner’s perspective. And since the black-and-white TruViews use the scan data, additional lighting is not required, as it would be with the color photograph TruViews.

Added Value: Though the fire water main was the only pipe modeled, the point cloud contains other key dimensional data, such as elevations, that can be used to provide sub-contractors with an accurate view of the current/as-built condition for other operations, such as demolition.

If you have a complex space for which you need to accurately capture the as-is condition and, especially, if you need it done quickly, 3D laser scanning is a safe and cost-effective way to do it. Contact us today at 734-807-0117 or annarbor@truepointscanning.com to discuss your needs.

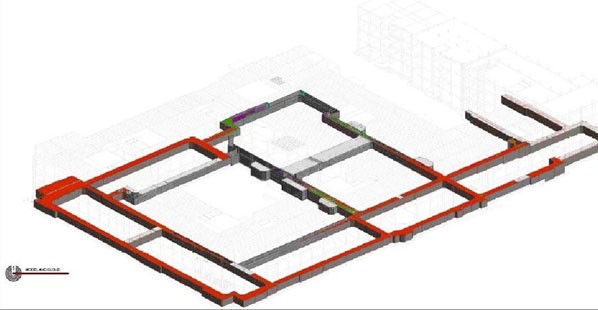

Our Revit 2014 utility tunnel model shown with the client’s engineering model of above structure.

Elevation details of a section of tunnel with the point cloud showing the fire water main.

Overall view of tunnel with walls, floor mesh, pipe run using AutoDesk reality capture software.

Cut section of Point Cloud and model showing floor, walls, various pipe runs, pipe connections, hangars, and other details.