TruePoint 3D laser scanned the interior and exterior of a transmitter facility in one day without interruption to station activities.

Case Study: 3D Laser Scanning A Mechanical Room of a Transmitter Station To Develop A 3D Model

CLIENT TESTIMONIAL:

“Thanks for jumping into this assignment so quickly. What a great and productive trip. You guys work tirelessly, non-stop with all aspects of the set-up and execution. Your ability to master the technology is a game changer for the spectrum repack.”

- Don A., Executive Vice President, Director of Architecture, Engineering and Technology for the Engineering Company

Location: Jacksonville, Florida

Task: TruePoint provided laser scanning services with the primary objective of developing a 3D model of a mechanical room. The room was approximately 60 feet by 80 feet and located in a transmitter facility in Jacksonville, Florida. TruePoint’s targets of acquisition included the interior structure, MEP equipment, and exterior walls of the mechanical room.

Challenge: The FCC can shake up the spectrum and require stations to change transmission frequencies. The client needed accurate measurements of the existing space and equipment to successfully plan and design changes mandated by the FCC. The room was filled with sensitive equipment and operations could not be disturbed.

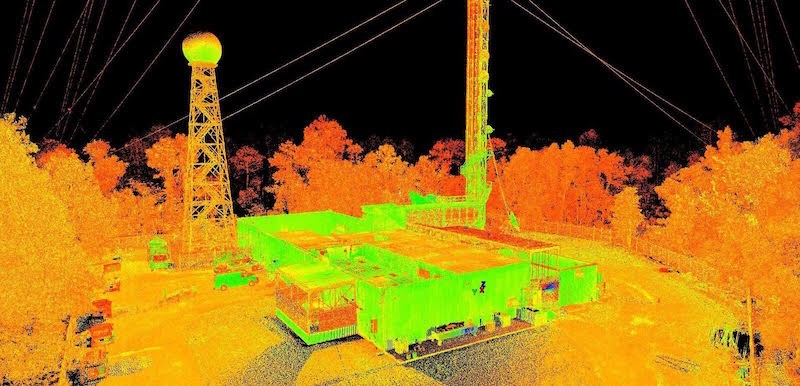

Solutions: TruePoint 3D laser scanned the interior and exterior of the transmitter facility in one day without interruption to station activities and created 3D as-built documentation of the facility. TruePoint in-house engineers and CAD technicians created a 3D Revit model directly from the point cloud.

Deliverables: TruePoint delivered a 3D model of the piping utilizing Edgewise software, a point cloud (.rcs files) and TruViews which are 360° 3D photographs overlaid on top of the point cloud data.

Added Value: There was little room for modifications in the mechanical room. By laser scanning to develop a 3D model the client could plan for the changes to the mechanical room before execution. In this project, extensive information was captured by the Leica C10 laser scanner, including areas that would normally be too dangerous, if not impossible to obtain. A Leica C10 scanner was selected for this project due to the 300 meter range capacity, which is greater than most similar scanners, in order to capture the entire tower from the ground. Laser scanners are non-contact, allowing scan technicians to capture detailed information at a safe distance. The laser scanner captured point cloud data of all towers, support wires, and satellite dishes – all without compromising safety or ongoing activities.

TruePoint’s team of Field Technicians and post-field Engineers, Architects and CAD Technicians is one of the industry’s most experienced. For laser scanning services in Florida, contact Andy Foshee at 904-903-8911 or email jacksonville@truepointscanning.com.

The transmitter mechanical room was approximately 60 feet by 80 feet.

Intensity map point cloud of the facility showing towers, guy wires and satellite dishes.

The client needed accurate measurements of the existing space and equipment to successfully plan and design changes mandated by the FCC.