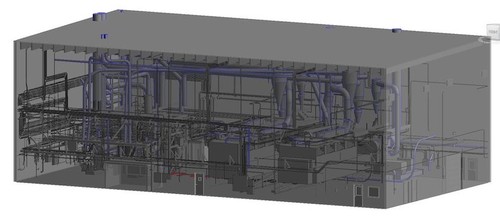

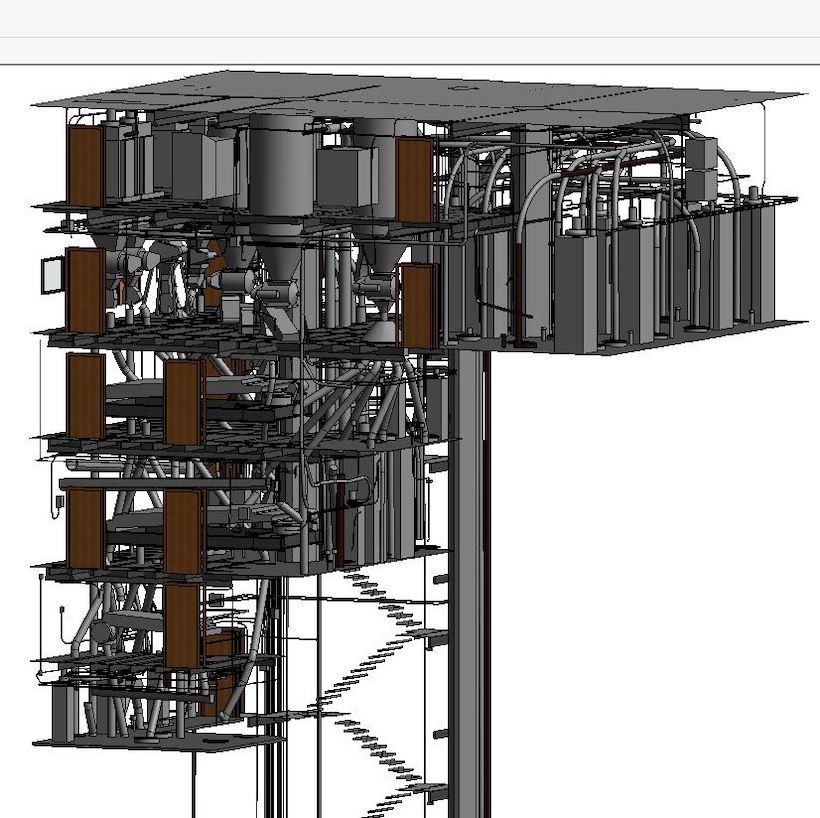

LOD 300 Revit model of extruder room.

Case Study: 3D Laser Scanning a Manufacturing Process Tower and Extruder Room

Location: Lebanon, Tennessee

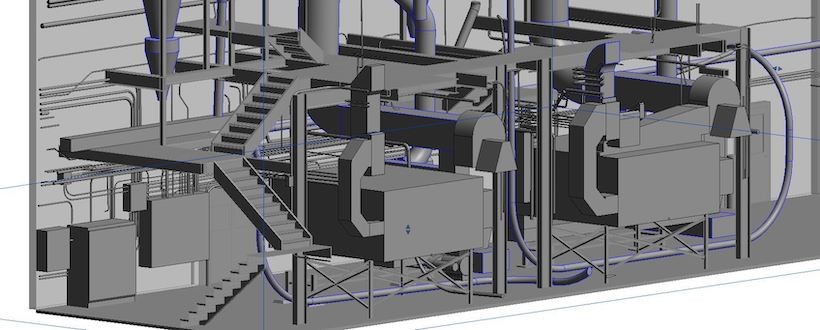

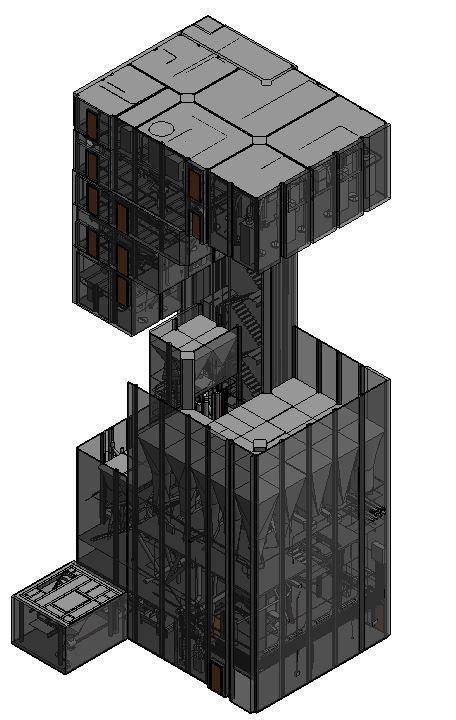

Task: TruePoint provided 3D laser scanning services for a process tower and extruder room in a manufacturing facility near Nashville, Tennessee. The extruder room and 11 levels of the tower were 3D laser scanned, including the structural layout, equipment footprints, dimensions of connections points, and piping tie-ins connecting the equipment. Point cloud data was collected in the project area and a 3D model was developed for the client.

Challenge: The client’s main objective in using laser scanning was to help them understand the as-is conditions of both the process tower and extruder room prior to removal and installation of equipment. For the extruder and process tower to operate efficiently, the equipment must be installed with great attention to detail and maintained properly. 3D laser scan data is critical in this operation to remove and install new equipment and guarantee efficient manufacturing.

Solutions: Laser scanning captures as-built data rapidly. It can then be inserted into various 3D modeling platforms for planning and operational purposes, allowing the client and contractors to have consistent, accurate building data. TruePoint’s team of in-house CAD designers created an LOD 300 Revit model detailing the structural layout of tower and extruder room; the MEP dimensions and connection points. The client will be using the 3D model to precisely plan their steps for the removal of existing equipment, as well as, knowing the best options for the installation of new equipment and piping.

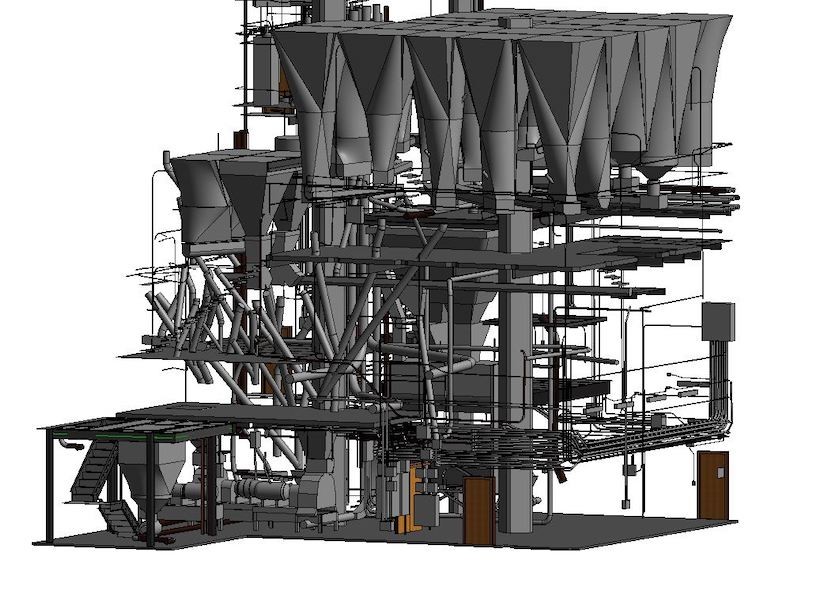

Deliverable: TruePoint CAD designers used multiple software programs to create two separate models for both the extruder room and the tower, one mechanical and one structural. TruViews, or interactive 360° photographs that are overlaid on top of the point cloud data, were created to assist in capturing the as-is conditions and detail of the process tower and extruder room.

Added Value: Having a team of in-house CAD designers helped to expedite this project for the client, and gives them access to these experts throughout their project.

If you are looking for 3D laser scanning services in Nashville, Tennessee, call 615-920-6464 or email nashville@truepointscanning.com.

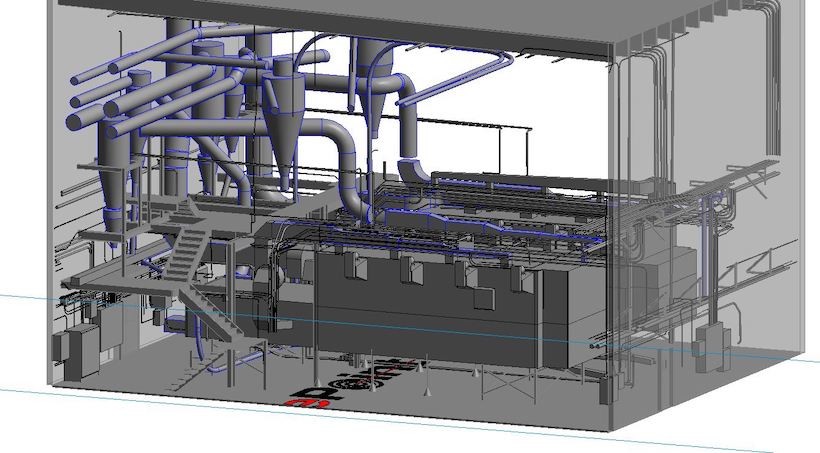

Close-up of mechanical and electrical elements in extruder room.

A 3D model gives the client and contractors accurate and consistent data for planning and operational purposes.

Having a team of in-house CAD designers helped to expedite this project for the client, and gives them access to these experts throughout their project.

Detail of tower equipment, chutes and piping 2" and above.

LOD 300 Revit model of 11-floor manufacturing process tower.