This dimensionally accurate baseline data set allows the client to measure and plan equipment installation before they mobilize to the field work phase.

Case Study: 3D Laser Scanning a Chemical Reactor

- “Planning within a virtual environment eliminates clashes and delays on project timelines. Our clients can go into projects with a plan of action and execute it efficiently.”

- David Sauceda - Texas Regional Manager

Location: Celina, Texas

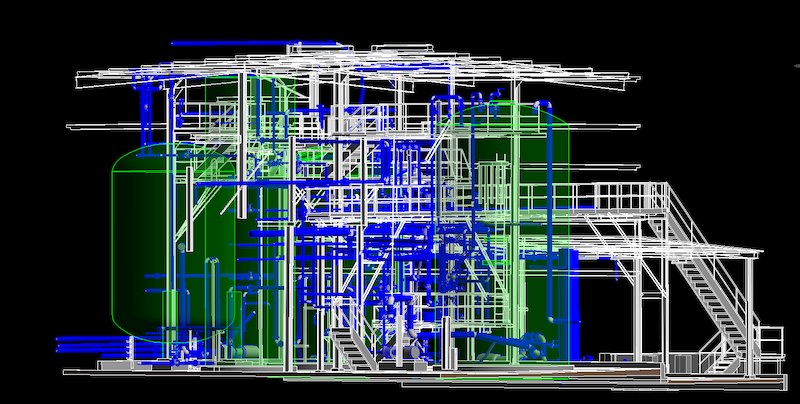

Task: TruePoint provided 3D laser scanning services for an industrial chemical and service company near Dallas, Texas to reality capture precise dimensions of a multi-level chemical reactor. Existing conditions were captured, including vessels, mechanical equipment, piping 2" and greater, pipe supports, flanges, valves, structural steel, stairs, handrails, platforms, grade and a cooling tower. The client received an LOD 350 AutoCAD model to design modifications to the chemical reactor.

Challenge: With no existing 3D model and outdated drawings, the client needed precise data to design upgrades to the reactor. The 3D model was critical in evaluating the pipes, fabricating tie-points at different heights and designing overall modifications to the site.

Solutions: Using a Leica survey-grade laser scanner, TruePoint’s Texas office captured the existing conditions of the chemical reactor. The client sent a complete 3D model to an engineering firm that could distinguish tie-points of each pipe and reinforce the piping structure. It allowed the firm to plan for design updates from their office, eliminating field visits.

Deliverable: TruePoint’s in-house team of CAD designers provided an LOD 350 AutoCAD model of the facility. They also provided intensity map point cloud files to detect any clashes that would cause field delays or change orders.

Added Value: A Revit model gives the client an easy to use, dimensionally accurate baseline data set so that they can measure and plan equipment installation before they mobilize to the field work phase.

TruePoint is a highly experienced team of 3D laser scanning professionals who deliver exceptional service, accurate data and custom deliverables to expedite your project. TruePoint can quickly mobilize to your site and provide free project quotes.

For 3D laser scanning services in Dallas Fort Worth call 214-551-6201 or email dallas@truepointscanning.com.

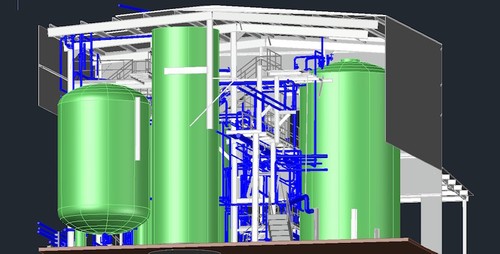

TruePoint's Dallas, Texas office captured precise dimensions of a chemical reactor.

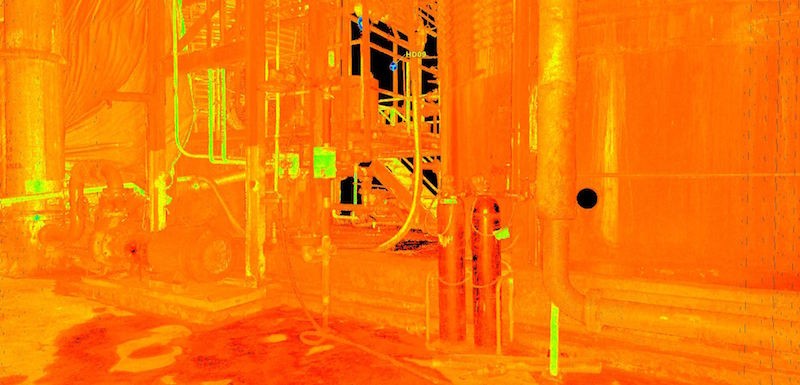

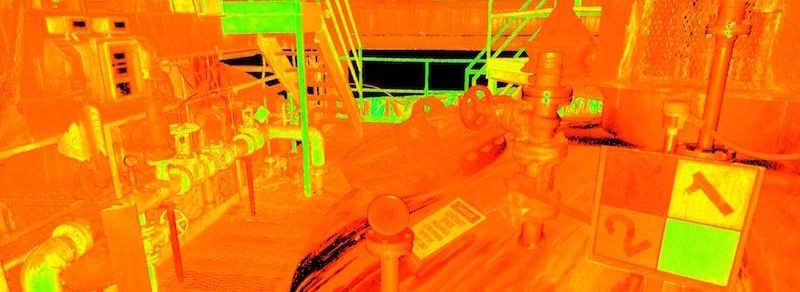

Revealed in another reality capture of the intensity map point cloud, this further shows platforms and handrails that are critical in pinpointing the location of each as they may interfere with any of the pipe supports.

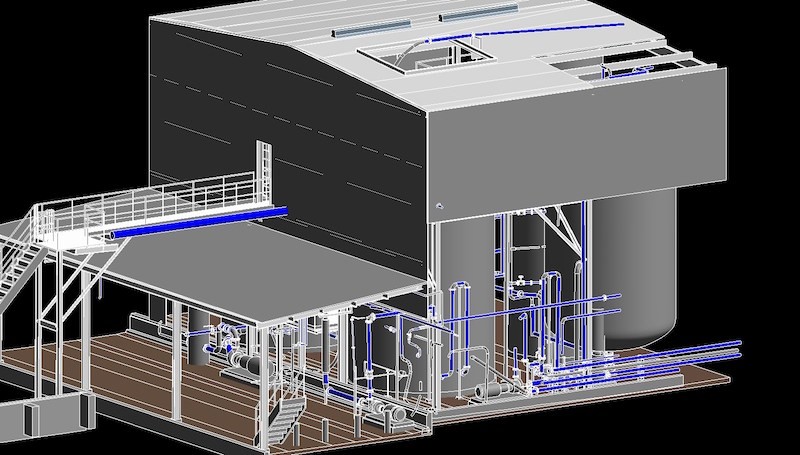

The existing conditions of the facility showing piping and nearby grade.

TruePoint collected accurate data of this multi-level structure using a Leica laser scanner.

TruePoint delivered an LOD350 AutoCAD model to the client to design modifications.

The 3D model was critical in evaluating the pipes, fabricating tie-points at different heights and designing overall modifications to the site.

This intensity map point cloud details the piping structure to determine where modifications can take place.