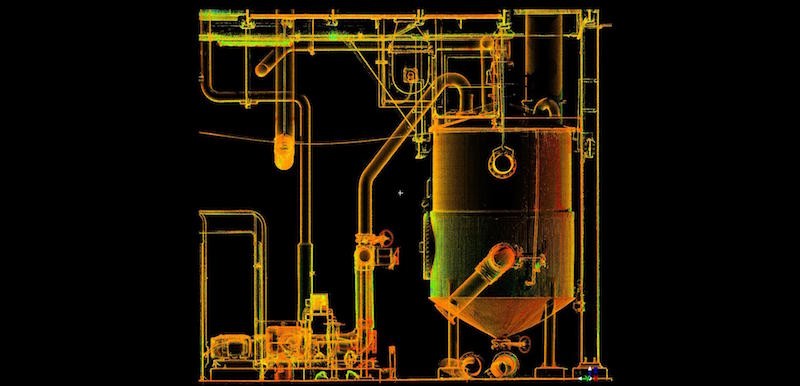

Laser scanning can easily and accurately capture piping on the second level of this facility.

Case Study: 3D Laser Scanning a Biochemical Processing Facility

Location: Raceland, Louisiana

Task: Provide high definition laser scanning services for a 50' x 50' x 20' area in a biochemical processing facility. The client was replacing pipes to a hydration tank pump and desired a 3D model to plan and fabricate the new pipes, ensuring proper fit and avoiding clashes. The objective for this laser scan was to capture vessels, piping, flanges, structural steel and pipe supports.

Challenge: The pumps in the facility were turned off and the piping was not active. Since the lines were not active, the client needed the x,y,z coordinates to add the necessary piping to the tie-points. Also, the area was complex, difficult to access and multilevel. The client would have to rent lifts to take measurements and traditional measurement methods would be challenging and possibly inaccurate.

Solutions: Using a Leica survey grade scanner, TruePoint’s scan technician laser scanned the area to capture as-built conditions. Scanning was completed on platforms and stairs to capture the entire multi-level facility. Once the data was registered, TruePoint’s in-house engineers used EdgeWise software to auto-extract piping from the point cloud and create an accurate 3D model for the client. The client used the point cloud to verify the tie-points and line sizes and the 3D model to design the new piping and flange connections.

Deliverables: TruePoint delivered a 3D model of the piping utilizing Edgewise software, a point cloud (.rcs files) and TruViews which are 360° 3D photographs overlaid on top of the point cloud data.

Added Value: According to the BIM Center web site, cost savings due to clash detection in the industry is about $17,000 per detected clash. Using laser scanning to create an accurate 3D model allows for prefabrication and clash detection prior to the installation of new piping or equipment. Mistakes which normally would have been discovered on the site can now be seen in the office even before anyone sets foot on the site. This saves both time and money.

TruePoint is a national provider of 3D reality capture laser scanning. For services in Louisiana, Oklahoma or Texas call David Sauceda at 713-818-2799 or email dsauceda@truepointscanning.com.

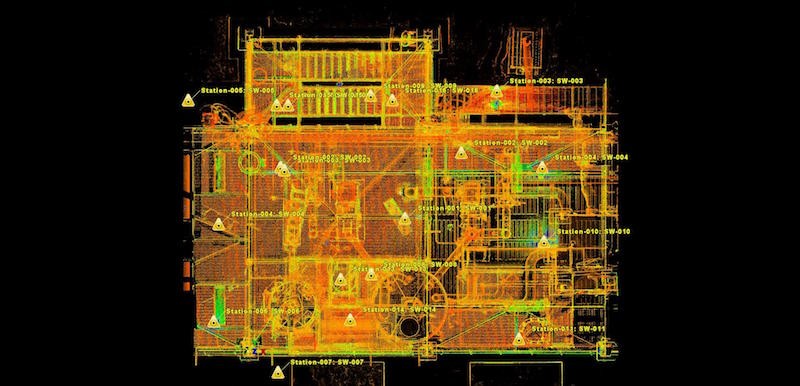

TruePoint created a site map of the facility.

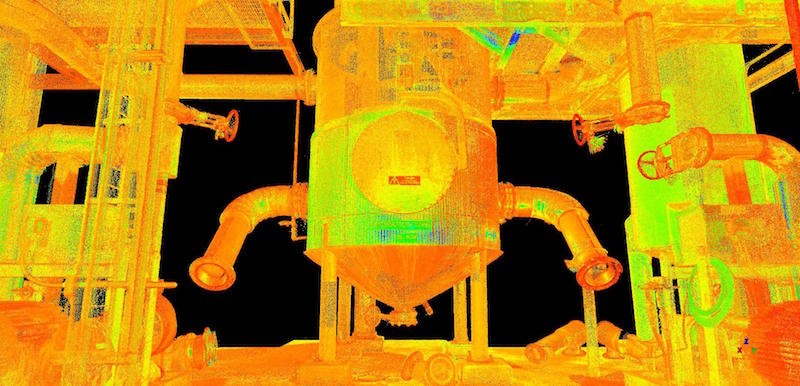

Intensity map point cloud data of the hydration tank pump.

The client used the point cloud to verify the tie-points and line sizes.

TruePoint provided high definition laser scanning services for a multi-level 50' x 50' x 20' area in a biochemical processing facility.

The client was replacing pipes to a hydration tank pump and desired a 3D model to plan and fabricate the new pipes, ensuring proper fit and avoiding clashes.