59 acres was 3d laser scanned in a 4-month period, sometimes with up to 10 scan teams on site at one time.

Case Study: 3D Laser Scanning a 59 Acre Wastewater Treatment Plant

“Our client wanted a quick turnaround on this project, with 27 buildings completely detailed in LOD 350 model, it was a huge undertaking that TruePoint completed successfully and within their needed timeline.” -- Aaron Hunt, Lead Technical Manager, TruePoint Laser Scanning

Location: Denver, Colorado

Task: 59 acres and 27 buildings were 3D laser scanned to provide complete as-built documentation of a Colorado Wastewater Treatment Plant. This client is the largest water reclamation provider in the Rocky Mountain West, serving 1.8 million people in a 715 square-mile area. TruePoint was tasked with 3D laser scanning the existing conditions of this $417 million facility and producing an LOD 350 Revit model to assist with on-going operations and plan for future expansion.

Challenge: The client needed the fastest way to document 59 acres and 27 buildings with the highest level of quality. Each building was unique and needed to be documented and modeled to plan for expansion, including pumping stations, sludge digester, thickener, tank reclamation, purification systems, aeration, primary and secondary settling, maintenance facilities and visitor center. The client had their own laser scanner, but did not have the manpower and resources to complete the project timely.

Solutions: TruePoint has a highly integrated and highly motivated team of laser scanning professionals. 59 acres of campus was 3d laser scanned in a 4-month period, sometimes with up to 10 scan teams on site at one time. TruePoint scan technicians captured 2,990 color scans and an in-house team of engineers produced a complete BIM model of the 27 buildings, including structural, architectural and MEP features.

Deliverable: TruePoint provided an LOD 350 Revit model of the interior and exterior of 27 buildings including architectural and structural details, MEP and process piping ½" and above, valves, flanges, equipment detail and location, stairwells, railings, closets, restrooms and janitor rooms. The client also requested EdgeWise files, so TruePoint CAD technicians modeled all piping, valves, flanges, ducts, conduit and framing and organized it in layers in accordance with the client’s naming conventions for location, plant process and material specifications. The client also used the BIM model to determine if the existing drawings reflected actual site conditions.

Added Value: 3D laser scanning enables clients to add, modify, validate and document their design digitally. 3d laser scanning allowed the plant to have a full scope of the existing conditions before renovations were made to the facility.

TruePoint has extensive experience 3D laser scanning water and wastewater treatment plants. We possess the passion, resources, experience and capabilities to provide a complete range of 3D laser scanning services. We are dedicated to providing clients exceptional service and can mobilize to any U.S. location quickly. For 3D scanning services in Denver, Colorado call 720-618-1029 or email denver@truepointscanning.com.

Client Testimonial: "We are striving to maintain digital twins of our wastewater treatment plant. TruePoint was very responsive and did an excellent job. They setup several meetings before scanning to understand our requirements and performed a walk-through of the plant. We do a lot of our own scanning, so we could speak the same language. We could have scanned it ourselves over time, but having them do it all at once really saved time. They provided a conversion to basic Revit 3D geometry, which saved us a big step. I only have a staff of six, so we were very glad to have found them for this project. In the end, I believe the data they handed over to us was on the order of 4-5TB. All in all, it was money very well spent." -- Patrick G. BIM|CAD Administrator

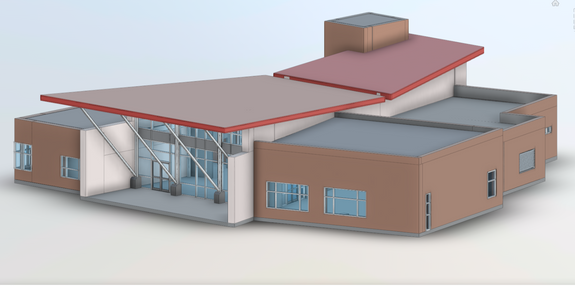

3D model of Visitor’s Center.

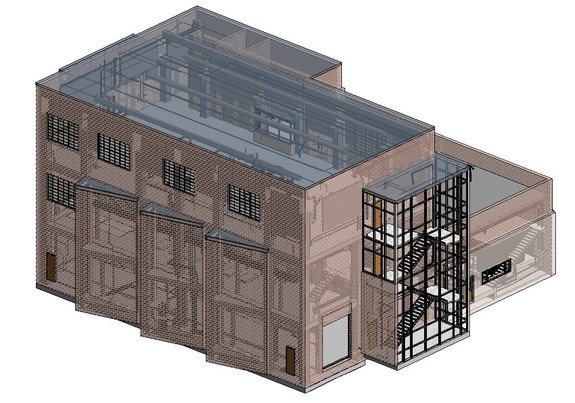

Exterior façade of the facilities support building.

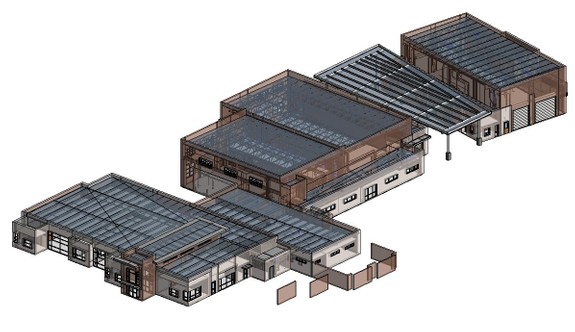

3D model of the Facilities Support Building.

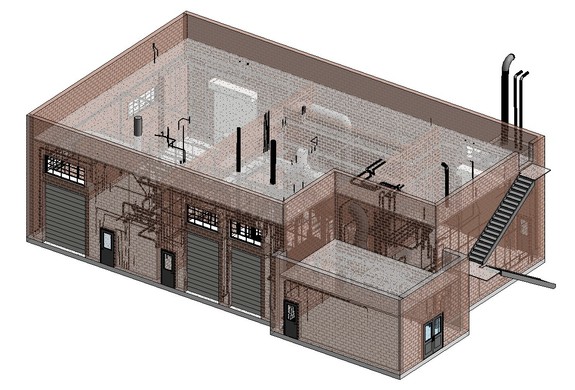

3D model of Chemical Storage Facility.

3D model of Bioreactors.

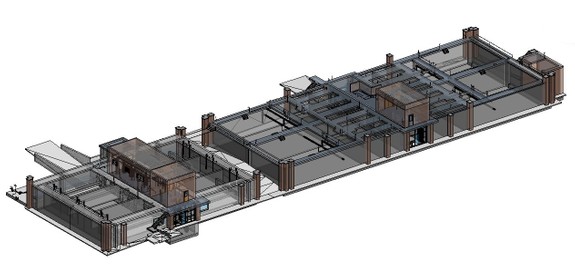

3D model of Tertiary Flocculation and Filters.

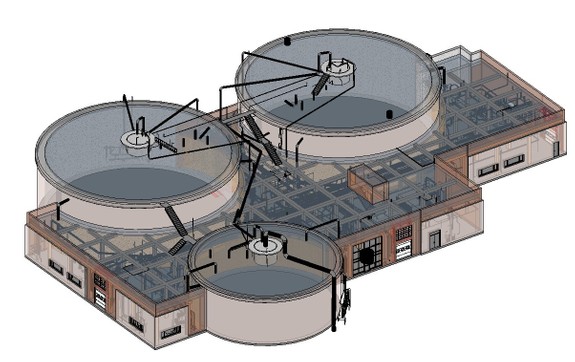

3D model of Digesters.

3D model of Dewatering Building.

3D model of Cogeneration Facility.

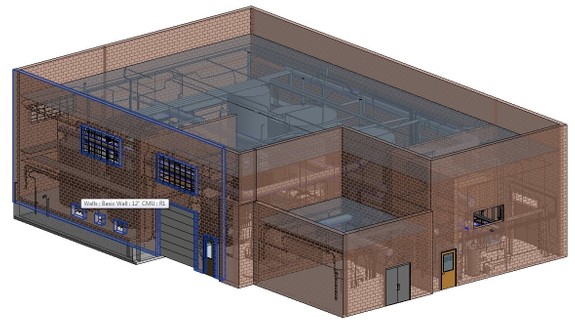

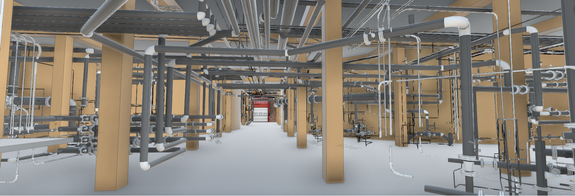

Screenshot detail of wastewater treatment plant interior.

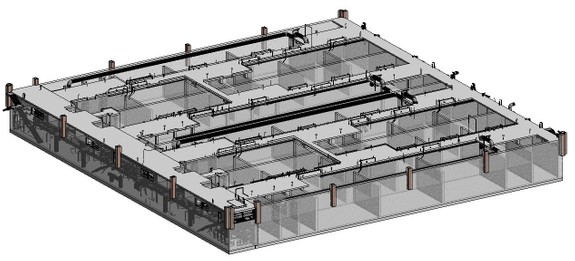

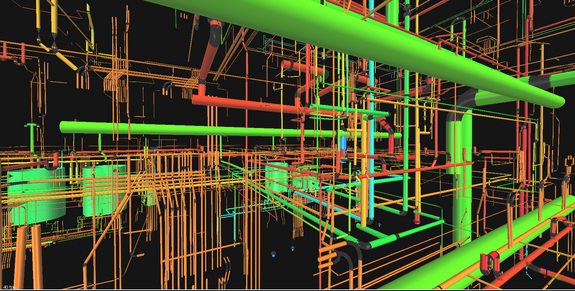

Using EdgeWise, TruePoint CAD technicians modeled all piping, valves, flanges, ducts, conduit and framing and organized it in layers in accordance with the client’s naming conventions.

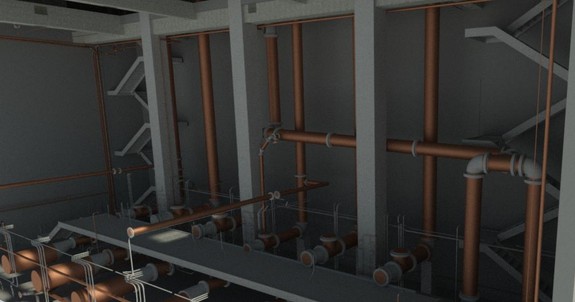

Closeup of pipe rendering in wastewater treatment plant.