3 Ways General Contractors Reduce Costs with 3D Laser Scanning

3 Ways General Contractors Reduce Costs with 3D Laser Scanning

3D laser scanning and mapping methodologies are commonly used to capture the most accurate data for every architectural, structural and MEP detail of your site. This technology is applicable throughout the design, construction, operations, retrofit, and renovation stages of any construction project’s lifecycle.

In a recent article published by Autodesk Inc., 3D laser scanning, “also known as high-definition surveying (HDS) or reality capture,” was described as a “means of using a laser to map an area with high accuracy,” for a given construction project.

Data collected from this process provides facility managers, engineers, and other construction professionals with what is known as a point cloud. This is a database, which connects points within a 3D coordinate system, maintaining an “extremely accurate digital record of an object or space as it pertains to a project.”

Given their ability to improve quality and accuracy, provide immediate information, reduce manual labor, streamline coordination, and greatly cut costs, it’s no surprise that 3D laser scanning techniques have grown in popularity over the past few years.

In an interview with Aaron Seymour of the Rudolph Libbe Group, Seymour explained how TruePoint 3D Laser Scanning is his choice measurement method for any construction project he’s assigned because it can save on time-consuming measurements and greatly cut costs. He elaborates on the fact that, "without the laser scanning capabilities that TruePoint provides, we would have to hire an architect that would have to go through and do manual assessments and measurements in order to provide us with a set of drawings that we can actually build off of," which is a far more expensive and lengthy process.

However, using the modern techniques of TruePoint Laser Scanning, we help project managers like Aaron fully visualize site data both above and below ground. Once all necessary data is collected by project managers and modeled by CAD technicians, it can then be easily stored and viewed using SiteMap®’s Map Viewer and Digital Plan Room.

There are three major ways in which 3D laser scanning can eliminate unnecessary costs for your construction project.

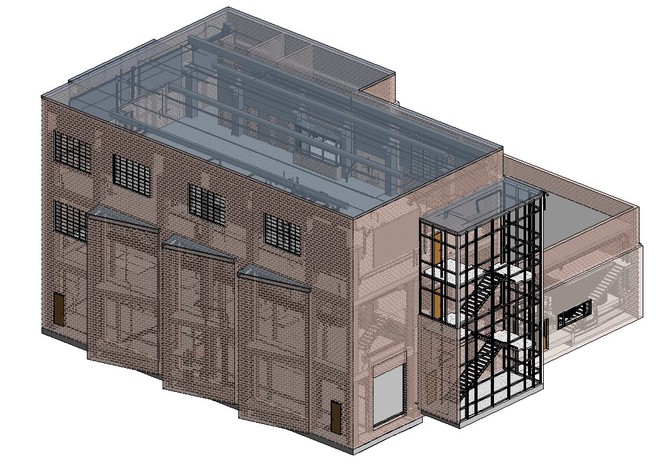

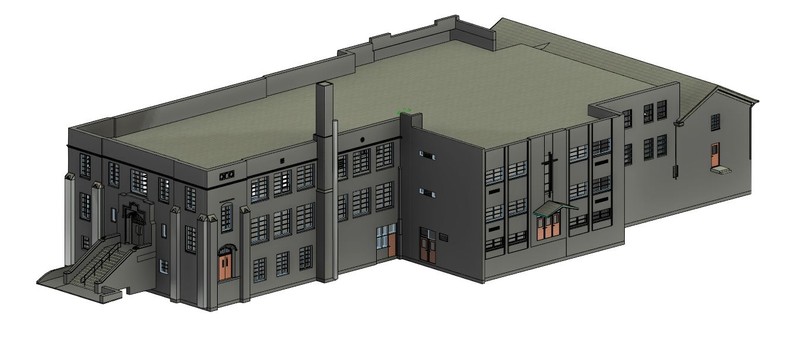

3D laser scanning captures the most accurate data for every architectural, structural and MEP detail of your site.

3 Ways Laser Scanning Can Reduce Costs

Measurement Accuracy

With more traditional methods of job site measurements, General Contractors usually have to hire an architectural firm to come in and manually collect all of the required measurements needed to create a set of drawings from which any construction plans or 3D model could be made.

However, this process has a very high chance of human error given that all measurements are taken and recorded by hand. This often results in inaccuracy up to a full foot, and therefore, major redesign costs later down the line after construction has already begun and such oversights stall any further progress.

On the other hand, with TruePoint 3D Laser Scanning Services, complete as-builts can be captured with a far more reliable 2-4 mm level of accuracy, eliminating the redesign costs associated with traditional hand measurement techniques.

Efficient, Time-Saving Data Collection

Typical hand measuring techniques can take months if not years to be completed. Such delays can be very costly and greatly jeopardize the success of any project.

However, using 3D laser scan technology, it will only take about 1-2 days in most cases for our Project Managers to completely scan a job site. Afterwards, our CAD team can interpret the collected data to accurately generate the comprehensive maps, models, and drawings your project needs to move forward.

This modernized process can assess any location with high precision, allowing our customers to confidently execute their vision in a matter of days instead of weeks or even months.

Customizable 3D Models

3D laser scanning is also great at minimizing cost particularly because of its flexible, customizable approach to 3D modeling project sites. Not all aspects of the project site need to be modeled. The features are modeled to your project’s specific scope and LOD, as defined in the proposal. By using these detail specifications to scope projects, precision requirements of the BIM model are clearly communicated for faster project execution. 3D BIM models are revolutionizing the way projects are delivered across industries, adding intelligence and efficiency to project execution.

3D models and additional deliverables are stored in SiteMap® for easy access and faster collaboration. SiteMap is a cloud-based digital platform designed to be an easy-to-use portal, containing your accurate, and up to date “as-built” drawings all in one place. Designed with an intuitive user interface, SiteMap® delivers permanent records of site assets and infrastructure.

In Conclusion

With 3D laser scanning, you can confidently plan and execute any project knowing our services provide the most accurate data and systems required to keep you and your team on time, on budget, and safe. We help those looking to Visualize The Built World™ by creating the most detailed maps and models for a fully comprehensive representation of their entire site, both above and below ground.

We aim to empower our clients with the tools they need to share their plans with subcontractors, designers, engineers, and others using an easy, streamlined approach. Learn more about how 3D laser scanning can save your project time and money while providing the most accurate results by downloading our brochures and contacting us for a quote today!

BIM models are created to your project's specific scope.